Unlocking Efficiency: How 3 Phase Frequency Converters Revolutionize Industrial Operations

In today's rapidly evolving industrial landscape, efficiency and productivity are paramount for staying competitive. One of the pivotal innovations driving this transformation is the 3 phase frequency converter, a powerful tool that enables seamless control of motor speeds and enhances overall operational flexibility. By converting input voltage and adjusting frequency, these converters not only optimize equipment performance but also significantly reduce energy consumption and operational costs.

This article delves into the myriad ways 3 phase frequency converters revolutionize industrial operations, empowering businesses to unlock new levels of efficiency. From improving process control to facilitating energy savings, the integration of this technology offers a compelling solution for industries aiming to enhance their productivity and sustain growth in a challenging economic environment.

Join us as we explore the transformative potential of 3 phase frequency converters and outline essential steps for implementing this game-changing technology in your operations.

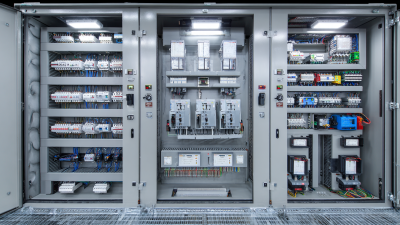

The Fundamentals of 3 Phase Frequency Converters: Understanding Their Role in Industries

Three-phase frequency converters play a crucial role in modern industrial operations, offering a sophisticated solution for managing electrical supply and enhancing machinery efficiency. By converting the frequency of the power supplied to motors, these devices allow industries to optimize their equipment performance and reduce energy consumption. According to a report by MarketsandMarkets, the global frequency converter market is projected to grow from $4.2 billion in 2020 to $5.9 billion by 2025, highlighting a significant demand for these converters in various sectors, including manufacturing, oil and gas, and renewable energy.

Understanding the fundamentals of three-phase frequency converters reveals their essential functionalities. These converters not only regulate motor speed and torque but also contribute to a reduction in operational costs by minimizing energy losses. A study published by the Electric Power Research Institute (EPRI) indicates that implementing frequency converters can lead to energy savings of approximately 20-50% in motor-driven systems. As industries increasingly adopt automation and smart technologies, the demand for efficient power management solutions like three-phase frequency converters continues to rise, facilitating a more sustainable and productive industrial environment.

Unlocking Efficiency: The Impact of 3 Phase Frequency Converters on Power Consumption

Key Advantages of Implementing Frequency Converters in Industrial Settings

In today's fast-paced industrial landscape, the implementation of three-phase frequency converters offers significant advantages that enhance operational efficiency and productivity. One of the primary benefits is the ability to optimize motor speed and torque without the need for mechanical gear changes. This capability allows industries to seamlessly adjust to varying load demands, resulting in energy savings and reduced wear on equipment. By maintaining optimal performance levels, businesses can minimize downtime and enhance the lifespan of their machinery.

Another key advantage is the improved control and precision that frequency converters provide. By enabling soft start and stop functions, these devices reduce mechanical stress during startup and shutdown, protecting both the motors and the driven equipment. Furthermore, advanced control algorithms allow for better process management, leading to enhanced product quality and consistency. The ability to integrate with automation systems also facilitates smart manufacturing practices, positioning industries to thrive in an increasingly competitive environment.

Transforming Energy Efficiency: How Frequency Converters Reduce Operational Costs

The advent of 3 phase frequency converters has brought a transformative shift in industrial operations, particularly in enhancing energy efficiency. These devices allow for precise control of motor speed, which not only optimizes performance but also leads to significant reductions in operational costs. By adjusting the frequency and voltage supplied to motors, businesses can tailor energy consumption to their specific needs, resulting in lower electricity bills and minimized energy waste.

To maximize the benefits of frequency converters, businesses should consider conducting regular maintenance checks. Ensuring that the converters are free from dust and debris can help maintain their efficiency. Additionally, investing in training for operators can enhance their understanding of the technology, leading to better operational practices that further reduce costs.

Another tip is to monitor your energy usage before and after the implementation of frequency converters. This data can provide insights into the effectiveness of the investment and highlight additional areas for improvement. By taking a proactive approach, companies can leverage frequency converters to not only cut costs but also contribute to a more sustainable and eco-friendly operation.

Unlocking Efficiency: How 3 Phase Frequency Converters Revolutionize Industrial Operations - Transforming Energy Efficiency: How Frequency Converters Reduce Operational Costs

| Aspect | Description | Impact |

|---|---|---|

| Energy Savings | Utilization of frequency converters to lower energy consumption in industrial equipment. | Up to 30% reduction in energy costs. |

| Operational Efficiency | Increased control over motor speed and torque. | Improved productivity and reduced downtime by 20%. |

| Equipment Longevity | Reduced wear and tear on motors through controlled acceleration and deceleration. | Extends equipment lifecycle by 40%. |

| Payback Period | Time required to recover the investment in frequency converters. | Typically less than 2 years. |

| Environmental Impact | Reduction of carbon footprint through lower energy consumption. | Decreases emissions by up to 25%. |

Case Studies: Real-World Applications of 3 Phase Frequency Converters in Industry

Three-phase frequency converters (3PFCs) are transforming industrial operations by enhancing efficiency and flexibility across various sectors. A recent report by MarketsandMarkets highlighted that the global market for frequency converters is projected to reach $7.7 billion by 2025, driven by their ability to optimize power supply and reduce energy consumption. Industries such as manufacturing, water treatment, and HVAC systems are experiencing notable advancements due to the implementation of 3PFCs. For instance, in the manufacturing sector, a leading automotive manufacturer reported a 20% reduction in energy costs after integrating 3PFCs into their production lines.

In the water treatment industry, the use of 3PFCs has propelled operational efficiency. A case study from a municipal water plant revealed that the facility achieved a 30% increase in pump efficiency by utilizing variable frequency drives (VFDs) linked to 3PFCs. By allowing for precise control of motor speeds, the plant was not only able to enhance throughput but also significantly lower energy waste. Additionally, in HVAC applications, buildings equipped with 3PFCs saw improved temperature control and significant savings on energy bills, with some reports indicating a decrease of up to 25% in overall energy consumption. These real-world applications underscore the profound impact of 3-phase frequency converters in revolutionizing industrial processes.

Future Trends: Innovations Shaping the Next Generation of Frequency Conversion Technology

The future of frequency conversion technology is being shaped by significant advancements in various fields, particularly in high-performance computing and artificial intelligence applications. As the demand for efficient industrial operations increases, the integration of cutting-edge technologies, such as photonic circuits, leads to faster and lower power consumption solutions. The global market for Linbo3 and Litao3 crystals, valued at $125 million in 2022, is projected to grow at a compound annual growth rate (CAGR) of 7.0% from 2024 to 2030, highlighting the increasing importance of these materials in innovative frequency conversion applications.

Moreover, recent trends in e-commerce further illustrate the dynamic landscape of technology. With consumers increasingly adopting augmented reality (AR) and virtual reality (VR) for enhanced shopping experiences, companies are leveraging AI for personalized recommendations. This shift creates new challenges regarding consumer data privacy and returns policies. Such transitions in various sectors emphasize the need for robust frequency conversion technologies to keep pace with the evolving industrial landscape, ultimately driving efficiency and innovation.

Related Posts

-

The Future of Solid State Frequency Converters Redefining Power Management

-

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency

-

Comprehensive Guide to Choosing the Right Voltage Frequency Converter for Optimal Performance

-

How to Choose the Right Solid State Phase Converter for Your Business Needs

-

How to Choose the Right Voltage Frequency Converter for Your Needs

-

Unveiling New Innovations: 400Hz Frequency Converters at the 138th Canton Fair 2025