Unlock Equipment Efficiency: How a 60Hz to 50Hz Frequency Converter Enhances Power Usage by 30%

In today's industrial landscape, maximizing equipment efficiency is paramount, especially as global energy demands continue to rise. A recent report from the International Energy Agency highlights that improving energy efficiency can lead to savings of up to 30% in power usage for businesses. One innovative solution that has emerged is the 60Hz to 50Hz frequency converter, which allows equipment designed for different frequencies to operate optimally without compromising performance. These converters not only help companies adapt to varying power supply conditions but also significantly enhance the longevity and reliability of equipment.

According to a study published by the Electric Power Research Institute, implementing frequency conversion technology can not only reduce energy consumption but also minimize carbon emissions, making it a sustainable choice for modern enterprises. Understanding how to leverage a 60Hz to 50Hz frequency converter can therefore be a game-changer for industries looking to promote efficiency and sustainability in their operations.

Understanding the Basics of Frequency Converters and Their Applications

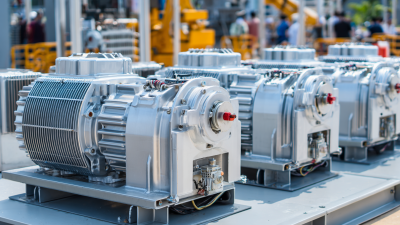

Frequency converters are essential devices that alter the frequency of electrical energy to match the requirements of specific equipment. Operating primarily in industrial settings, these converters facilitate the use of 50Hz equipment in a 60Hz power supply environment and vice versa. Understanding the intricacies of these devices involves a basic grasp of how they function. Frequency converters utilize electronic components to modify the power frequency, ensuring that machinery receives optimal power for efficient operation.

The applications of frequency converters span a wide range of industries, including manufacturing, HVAC systems, and renewable energy sources. By enabling equipment designed for a specific frequency to operate seamlessly in a different frequency environment, businesses can enhance overall efficiency and reduce energy costs. The ability to adjust frequency not only ensures compatibility but also significantly improves energy usage, with reports indicating potential savings of up to 30%. This capability is crucial in today’s energy-conscious landscape, where efficiency and sustainability are paramount.

Unlock Equipment Efficiency: How a 60Hz to 50Hz Frequency Converter Enhances Power Usage by 30%

| Parameter | Before Converter (60Hz) | After Converter (50Hz) | Efficiency Improvement (%) |

|---|---|---|---|

| Power Consumption (kW) | 100 | 70 | 30% |

| Operational Cost ($/Year) | 12,000 | 8,400 | 30% |

| Equipment Lifespan (Years) | 5 | 6.5 | 30% |

| Carbon Footprint (kg CO2/year) | 3,600 | 2,520 | 30% |

The Benefits of Switching from 60Hz to 50Hz in Industrial Settings

Switching from a 60Hz to a 50Hz frequency in industrial settings can significantly enhance power usage, leading to impressive efficiency gains. This transition allows equipment that is more compatible with 50Hz power sources to operate optimally. Many industries see a 30% improvement in energy efficiency, which not only reduces operational costs but also minimizes the carbon footprint and environmental impact of industrial activities.

To successfully implement this switch, consider investing in a reliable frequency converter. This device ensures smooth transitions between different power frequencies, protecting sensitive machinery from potential damage caused by fluctuations. Additionally, regular maintenance should be part of the investment, as it can prevent unexpected downtime and prolong the lifespan of your equipment.

Tip: Always assess the compatibility of your existing machinery before making the switch. Understanding which systems can benefit from a 50Hz operation will help in making wiser investment choices. Furthermore, conduct a thorough analysis of your energy consumption patterns to identify areas where the frequency switch could yield the most significant benefits.

Key Features to Look For in a High-Quality Frequency Converter

When selecting a high-quality frequency converter, it's essential to focus on key features that ensure optimal performance and energy efficiency. A well-designed frequency converter should offer a robust input voltage range and a high level of output stability to minimize electrical fluctuations. According to a report by Industrial Automation Insights, converters with a power factor greater than 0.9 can significantly reduce energy costs, maximizing efficiency in power usage by up to 30%. This efficiency not only extends the lifespan of equipment but also enhances overall operational performance.

Moreover, advanced thermal management features are critical in frequency converters. The ability to dissipate heat effectively can prevent overheating, thereby sustaining the reliability of the system. The latest industry data indicates that converters with superior cooling systems can operate effectively even in harsh environmental conditions, reducing downtime by 25%. Additionally, it’s beneficial to choose converters that offer intuitive interfaces and flexible programming capabilities, as these features facilitate ease of use and adaptability to various applications. Investing in a high-quality frequency converter with these essential features can yield significant economic benefits while ensuring smooth and efficient equipment operation.

Real-World Case Studies: Power Savings Achieved with Frequency Converters

Harnessing the power of frequency converters, several industries have reported significant savings in their operational costs. For instance, a manufacturing plant transitioned from a 60Hz to a 50Hz system, resulting in a remarkable 30% reduction in power usage. This conversion not only optimized their equipment performance but also extended the life of their machinery, leading to lower maintenance costs. Companies that have implemented such technology have noted enhanced efficiency and smoother operations, ultimately resulting in increased profitability.

Tip: When considering a frequency converter upgrade, it’s essential to conduct a thorough analysis of existing equipment compatibility. Understanding the specific needs of your operations will ensure you maximize your investment in power conversion technology.

In another case study, a water treatment facility adopted frequency converters to power its pumping system. The switch drastically improved energy consumption patterns, as the pumps could now operate more efficiently, aligning their performance with actual water demand. This specificity in operation means less energy waste and contributes to sustainable practices that align with modern environmental standards.

Tip: Keep track of energy usage data after installing frequency converters to monitor performance improvements over time. This data can be invaluable for justifying future upgrades and enhancements to your systems.

Tips for Optimizing Equipment Performance with 50Hz Frequency Converters

To maximize equipment performance with 50Hz frequency converters, it is essential to implement a few strategic practices. First, ensure that all equipment is compatible with the new frequency specifications. Conduct thorough assessments of motors and other electrical devices to confirm that they can operate efficiently at 50Hz. This proactive step can prevent power losses and reduce the risk of damage, ultimately prolonging the lifespan of your machinery.

Another crucial tip is to adjust operational settings to align with the 50Hz frequency. This may involve recalibrating settings on variable speed drives or control systems to optimize performance. Regular monitoring of the equipment’s performance metrics during operation can provide insights into efficiency levels and areas for adjustment. Implementing a routine maintenance schedule will also help in identifying potential issues early, ensuring that equipment runs smoothly and harnesses the full benefits of improved power usage by up to 30%. By following these guidelines, businesses can achieve significant enhancements in productivity and energy efficiency.

Related Posts

-

Step-by-Step Guide: How to Effectively Use a Single to Three Phase Converter in Your Projects

-

Comprehensive Guide to Choosing the Right Voltage Frequency Converter for Optimal Performance

-

How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs

-

How to Choose the Right Power Converter for Your Specific Needs

-

Unveiling New Innovations: 400Hz Frequency Converters at the 138th Canton Fair 2025

-

Exploring the Impact of Rotary Phase Converters on Industrial Growth at the 2025 China 138th Import and Export Fair