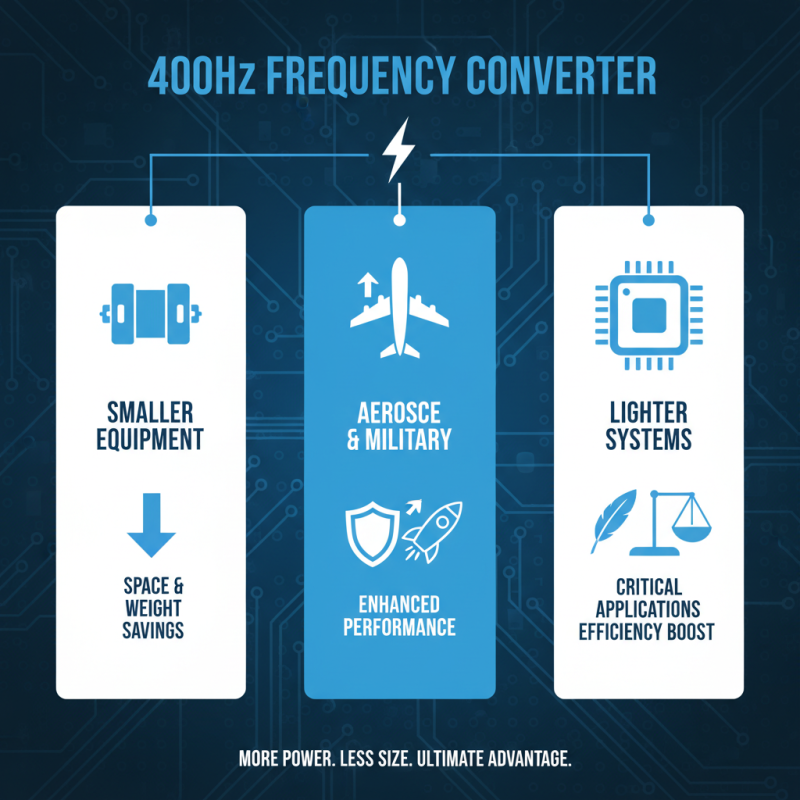

Top Benefits of Using a 400Hz Frequency Converter for Your Applications

In the world of industrial power solutions, the 400Hz frequency converter stands out. Recognized for its ability to optimize performance, this technology is integral for various applications. As noted by industry expert Dr. Jessica Lane, “The efficiency of a 400Hz frequency converter can transform how systems operate.”

These converters enable lightweight equipment design, crucial in aviation and military sectors. They reduce weight while maintaining power reliability. This offers a competitive edge but can also lead to increased costs upfront. Organizations must weigh these factors carefully.

Some might overlook maintenance needs associated with 400Hz systems. Proper management is vital for longevity. As technology progresses, the benefits and challenges of these converters become clearer. Companies must remain adaptable and proactive to harness their full potential in dynamic environments.

Understanding 400Hz Frequency Converters and Their Applications

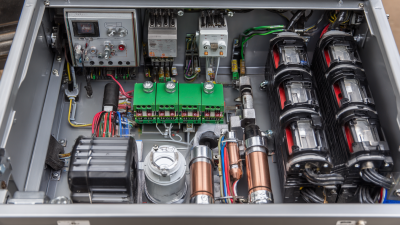

In industrial applications, 400Hz frequency converters are becoming increasingly important. These devices convert power frequency from 50Hz or 60Hz to 400Hz, enabling efficient operation of specialized equipment. The aerospace and military sectors primarily benefit from this technology. The use of 400Hz reduces the size and weight of electrical systems, contributing to overall efficiency.

According to a recent report by the International Electrotechnical Commission, 400Hz systems can reduce the weight of power distribution systems by up to 50%. This is critical in aerospace applications where weight savings directly impact fuel efficiency. Furthermore, many devices operating at 400Hz experience improved performance and reliability, which is essential for mission-critical operations.

However, it’s essential to note that translating a system to 400Hz isn't without challenges. Equipment designed for standard frequencies may require modifications for optimal performance. Additionally, power quality issues must be addressed to prevent malfunctions. Regular assessments of the frequency converter's output can help identify potential issues early on, ensuring smoother operations.

Key Advantages of 400Hz Frequency Converters in Power Supply

When it comes to power supply systems, 400Hz frequency converters offer significant advantages. One key benefit is their ability to reduce the size and weight of power equipment. With higher frequencies, components like transformers and capacitors can be smaller. This makes installations more compact and transport easier. It’s a game-changer in aviation and military applications where every ounce counts.

Another major advantage is improved efficiency. Equipment operating at 400Hz can draw less current to achieve the same power output. This leads to reduced heat generation. Consequently, the need for cooling systems diminishes. However, users must be aware of compatibility issues. Not all devices are designed for 400Hz operation, which requires careful consideration.

Flexibility is another notable benefit. 400Hz frequency converters can adapt to various applications. They are ideal for powering sensitive electronic devices. Yet, it’s crucial to ensure that the chosen converter meets specific requirements. Oversizing can lead to inefficiencies, whereas undersizing may cause reliability issues. Users should conduct thorough evaluations before making decisions, keeping in mind the distinct needs of their setup.

Top Benefits of Using a 400Hz Frequency Converter for Your Applications

| Benefit | Description | Application Examples |

|---|---|---|

| Improved Efficiency | 400Hz equipment operates more efficiently, reducing energy consumption and operational costs. | Military aircraft, aerospace systems, and high-performance computing. |

| Compact Size | Smaller transformers and generators can be used, saving space in installations. | Satellite systems, portable ground power units. |

| Enhanced Performance | Higher frequency increases the performance of electric motors and other equipment. | Industrial automation, robotics, and avionics. |

| Lower Weight | 400Hz converters and associated equipment are lighter, making them ideal for mobile applications. | Airport ground power, marine applications. |

| Reliable Power Supply | Provides stable and consistent frequency output, crucial for sensitive equipment. | Data centers, telecommunications, and medical equipment. |

Enhanced Efficiency and Performance: Why 400Hz Matters

A 400Hz frequency converter significantly enhances efficiency in various applications. Higher frequency allows for smaller equipment, which can save space and reduce weight. In aerospace and military technology, this increased efficiency can lead to better performance in critical situations. Smaller components mean lighter systems, which is crucial when every ounce counts.

Using a 400Hz frequency converter can also improve power management. It reduces losses in electrical systems, leading to better energy consumption. However, there are challenges. Not all existing equipment is compatible with this frequency. Upgrading systems can be costly. Many organizations hesitate due to these expenses, even if the benefits are clear.

One must also consider the operational environment. Some installations may require additional cooling systems due to increased heat generation at higher frequencies. This is a trade-off that should not be overlooked. Optimization is key, yet achieving it can involve a learning curve. There’s room for improvement in how industries adapt to these advanced systems.

Applications of 400Hz Frequency Converters in Aerospace and Defense

The aerospace and defense industries rely heavily on 400Hz frequency converters. These converters provide stable power for various systems. They are crucial in aircraft power supply, radar systems, and other applications where reliability is key. According to a recent industry report, approximately 70% of modern aircraft utilize 400Hz systems for optimal performance.

In aircraft, 400Hz frequency converters help save weight and space. Traditional 50Hz systems are bulkier and less efficient. The switch to higher frequency means smaller transformers and generators. This change leads to significant weight reductions. For example, the U.S. military has reported reductions of up to 30% in weight for certain platforms. However, the transition isn't always smooth. Some older systems may require retrofitting, which can be costly.

Defense applications also benefit from 400Hz frequency converters. They ensure that critical defense equipment operates correctly under demanding conditions. High-frequency converters improve the efficiency of electronic warfare systems and communication devices. Yet, implementing these systems raises concerns about electromagnetic interference. This issue merits further investigation. Addressing such challenges is vital for maintaining performance and reliability in critical applications.

Cost Savings and Reliability Benefits of Using 400Hz Converters

In modern industries, the adoption of

400Hz frequency converters has surged due to their cost-saving potential.

According to industry reports, these converters can reduce power consumption by up to 30%.

This is significant, especially in high-demand environments like aviation and military sectors.

A 400Hz system operates more efficiently, allowing smaller transformers and lighter cabling,

which further cuts costs.

Reliability is another benefit of utilizing

400Hz converters. They are designed to handle demanding applications

and maintain performance under pressure. Reports indicate that equipment powered by 400Hz systems

experiences fewer failures. This translates to reduced maintenance costs and downtime. In fact,

organizations have reported a 20% decrease in repair times,

which enhances operational efficiency.

However, switching to a 400Hz system isn't always a smooth transition. It requires careful planning and analysis.

Some companies face challenges in integrating these systems with existing infrastructure. Unexpected costs can arise during installation,

leading to budget overruns. Despite these hurdles, the long-term savings and reliability often outweigh initial investment concerns.

Businesses must weigh these factors to make informed decisions.

Related Posts

-

Unveiling New Innovations: 400Hz Frequency Converters at the 138th Canton Fair 2025

-

Best 3 Phase 400Hz Frequency Converter Options for Optimal Performance

-

10 Reasons Why Solid State Frequency Converters Are Revolutionizing Global Supply Chain Efficiency

-

Unlocking Efficiency: How 3 Phase Frequency Converters Revolutionize Industrial Operations

-

5 Essential Tips for Choosing the Right VFD Phase Converter to Maximize Efficiency

-

Top 5 Benefits of Converting Single Phase to 3 Phase Power Systems