Best 3 Phase 400Hz Frequency Converter Options for Optimal Performance

In the realm of industrial power solutions, the importance of a reliable 3 phase 400Hz frequency converter cannot be overstated. As the demand for aircraft ground power, military applications, and specialized industrial equipment continues to surge, selecting the right converter becomes crucial for operational efficiency. According to Dr. John Anderson, an industry expert at the International Electrical Engineering Society, "A quality 3 phase 400Hz frequency converter not only enhances performance but also ensures the longevity of sensitive electronic systems.”

Understanding the mechanisms and advantages of 3 phase 400Hz frequency converters is essential for professionals seeking optimal performance in their operations. These converters are engineered to transform standard 50 or 60 Hz power into the high-frequency 400Hz format, which is essential for a variety of applications, especially in the aviation and defense sectors. By converting the frequency effectively, users can achieve improved power efficiency and reduced weight in their power systems, which are significant factors in both operational costs and performance metrics.

As the industry evolves, so do the technologies associated with frequency conversion. This article aims to explore the best options available in the market for 3 phase 400Hz frequency converters, highlighting features and advancements that contribute to superior performance. By making informed decisions, operators can ensure that their equipment runs smoothly and efficiently, thereby optimizing overall functionality and productivity.

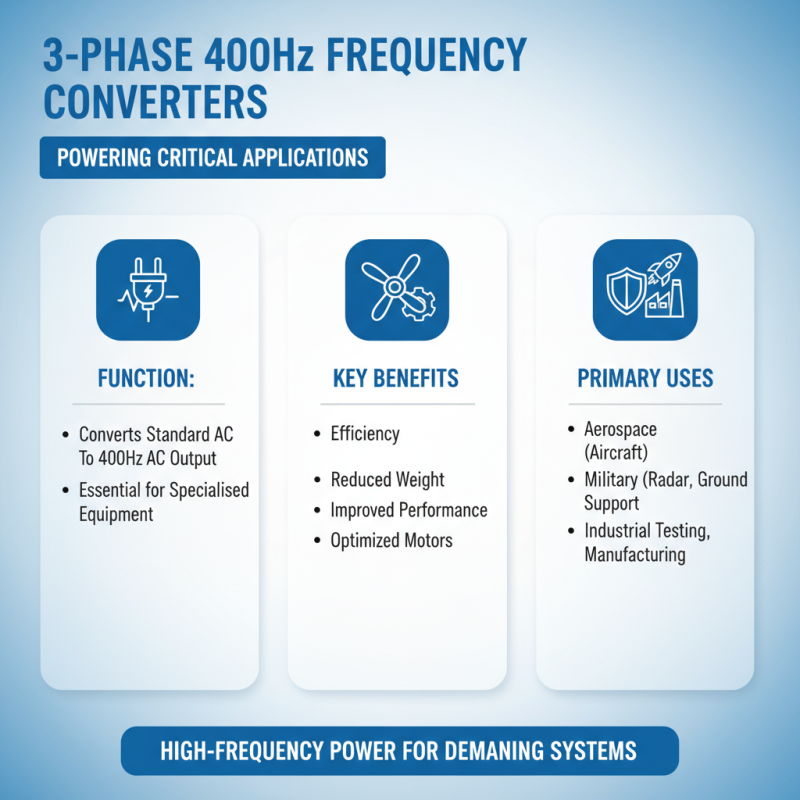

Overview of 3 Phase 400Hz Frequency Converters

3 phase 400Hz frequency converters play a crucial role in various applications, particularly in aerospace, military, and industrial settings where high-frequency power is essential. These converters are designed to transform standard alternating current (AC) power to a 400Hz output, catering to the specific needs of equipment that operate at this frequency. The requirement for this frequency arises mainly from the efficiency benefits and performance optimizations it offers for motors and other electrical components, allowing for reduced weight and improved operational capacity.

The architecture of 3 phase 400Hz frequency converters involves sophisticated designs that ensure stability, reliability, and high efficiency. These devices typically employ advanced technologies such as PWM (Pulse Width Modulation) to produce a clean and precise frequency output, essential for sensitive electronic equipment. Additionally, many converters are equipped with safety features and protections against overloads, short circuits, and thermal issues, which are critical in maintaining operational integrity under varying load conditions. As industries continue to demand higher performance from their electrical systems, the importance of selecting the right 3 phase 400Hz frequency converter becomes increasingly significant, driving innovation and enhancing overall system effectiveness.

Key Features to Consider in 400Hz Frequency Converters

When selecting a 400Hz frequency converter, several key features are pivotal for ensuring optimal performance. First and foremost, users should consider the converter's efficiency and power output capabilities. According to research from the Electrical Engineering Handbook, high-efficiency converters can reach efficiency levels exceeding 95%, which is crucial for reducing energy costs and extending the lifespan of connected equipment. Additionally, the power quality should be scrutinized, with a focus on total harmonic distortion (THD) levels. A lower THD, ideally below 5%, is recommended to ensure stable operation and minimal interference with sensitive electronic devices.

Another critical aspect is the design and build quality of the frequency converter. Robust construction not only enhances durability but also improves thermal management, which is essential for maintaining performance under heavy loads. The American National Standards Institute (ANSI) emphasizes that the use of high-quality materials can reduce failure rates and minimize maintenance needs. Furthermore, features such as overload protection and user-friendly interfaces should be considered, as they contribute significantly to the ease of operation and safety.

Tips: Always assess the specific application requirements before making a choice. Operations with varying loads may benefit from converters with adaptive control technologies that adjust performance in real-time. Regular maintenance checks are also advisable to keep the converter functioning efficiently and to prevent unexpected downtime.

Best 3 Phase 400Hz Frequency Converter Options for Optimal Performance

| Model | Input Voltage (V) | Output Voltage (V) | Power Rating (kVA) | Weight (kg) | Efficiency (%) | Key Features |

|---|---|---|---|---|---|---|

| Model A | 380 | 400 | 30 | 150 | 95 | Compact design, Overload protection |

| Model B | 400 | 400 | 50 | 200 | 92 | User-friendly interface, Reliable output |

| Model C | 415 | 400 | 75 | 250 | 97 | Low noise operation, Portable |

| Model D | 380 | 400 | 100 | 300 | 90 | Integrated monitoring, Overvoltage protection |

Top Brands and Models of 3 Phase 400Hz Frequency Converters

When choosing the best 3 phase 400Hz frequency converters, it's essential to consider several top brands and models that are renowned for their reliability and performance. Key features to look for include efficiency, ease of installation, and versatility in adapting to various applications. Leading manufacturers often incorporate advanced technology to ensure stable output and minimal distortion, which is crucial for sensitive equipment requiring 400Hz power supply.

Tip: Always assess the power rating and load requirements of your intended application before making a decision. Understanding the specific needs will help in selecting the right model that balances performance and cost-effectiveness.

In addition to performance metrics, the quality of customer support and after-sales service can significantly impact your overall experience. Opt for brands that offer comprehensive service plans and warranties, ensuring you have support should any issues arise.

Tip: Conduct thorough research on user reviews and experiences with different models. Engaging with existing users can provide insight into the durability and reliability of the converters you're considering, aiding in a more informed decision.

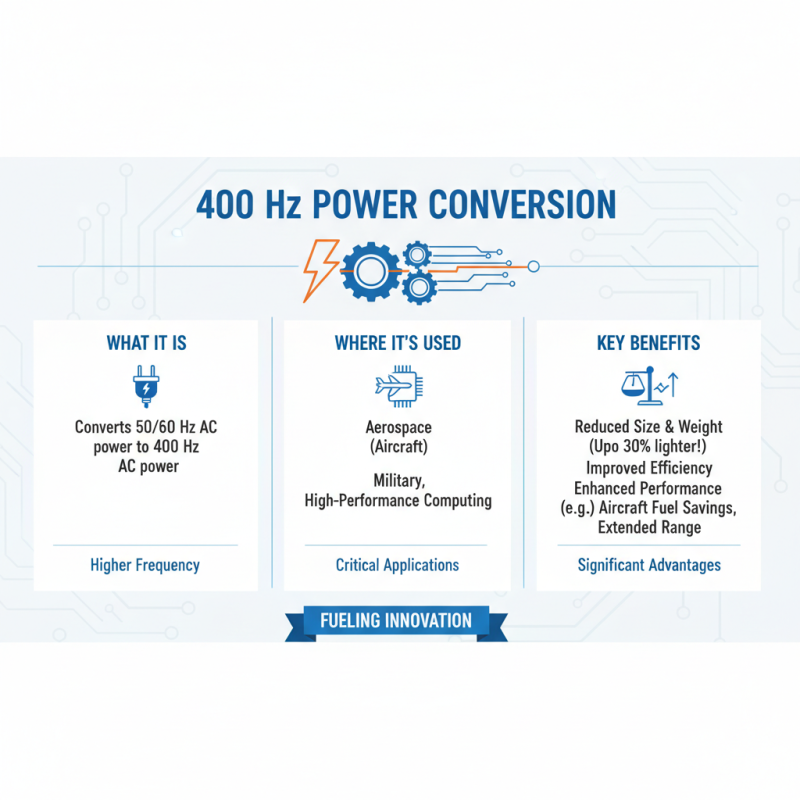

Applications and Industries Utilizing 400Hz Frequency Conversion

The conversion of 50/60 Hz power to 400 Hz frequency is vital in various applications, particularly in aerospace, military, and high-performance computing sectors. The demand for 400 Hz frequency conversion stems from its ability to reduce the weight and size of electrical systems. For example, aircraft, such as the Boeing 787, utilize 400 Hz power systems to improve efficiency and performance, as lighter equipment results in fuel savings and enhanced flight range. According to a report by the International Journal of Electrical Power & Energy Systems, incorporating 400 Hz systems can lead to a reduction in overall system weight by up to 30%, which is significant for aviation applications.

Moreover, industries such as telecommunications and data centers are increasingly adopting 400 Hz systems to power their operations. The higher frequency allows for smaller transformers and cables, which can be crucial in space-constrained environments. A study from the IEEE (Institute of Electrical and Electronics Engineers) emphasizes that equipment powered by 400 Hz frequency can handle higher power loads while maintaining lower thermal outputs, leading to increased reliability and extended lifespan for sensitive electronic devices.

**Tip:** When selecting a 400 Hz frequency converter, consider the total harmonic distortion (THD) figures. A lower THD rating ensures that the power delivered to your equipment is cleaner, leading to improved efficiency and reduced risk of damage to sensitive electronics.

**Tip:** For applications in variable load conditions, opt for frequency converters with adaptive control systems. These can adjust the output frequency and voltage dynamically, ensuring optimal performance across different operational scenarios, thus enhancing the overall functionality of your power systems.

Maintenance Tips for Optimal Performance of Frequency Converters

Frequency converters are crucial for various applications that require specific power needs, especially in aerospace and industrial settings. However, to maintain optimal performance of a 3-phase 400Hz frequency converter, regular maintenance is paramount. According to the Electrical and Electronics Engineering Society, a well-maintained frequency converter can ensure up to 20% more efficiency, thus prolonging the equipment's lifespan and minimizing the total cost of ownership.

To ensure optimal performance, it is essential to perform routine inspections, including visual checks for dust accumulation and ensuring proper cooling airflow. Additionally, regular testing of all electrical connections can prevent overheating and maximize energy efficiency. Research by the International Energy Agency indicates that neglecting these maintenance tasks can lead to significant energy losses, often exceeding 10% annually. Implementing a scheduled maintenance plan not only enhances the reliability of frequency converters but also ensures compliance with safety standards, ultimately driving down operational costs.

Best 3 Phase 400Hz Frequency Converter Options for Optimal Performance

This chart shows the efficiency percentages of various 3-phase 400Hz frequency converters, highlighting their performance for optimal usage. Consider these options for effective power conversion.

Related Posts

-

The Future of Solid State Frequency Converters Redefining Power Management

-

Unveiling New Innovations: 400Hz Frequency Converters at the 138th Canton Fair 2025

-

Understanding the Benefits of Using a 400hz to 60hz Converter for Your Electrical Systems

-

Unlocking Efficiency: How 3 Phase Frequency Converters Revolutionize Industrial Operations

-

Understanding the Transition: How a 60 Hz to 50 Hz Frequency Converter Can Enhance Energy Efficiency in Industrial Applications

-

Ultimate Guide to 400Hz to 60Hz Converters: Top Picks for 2025