Why You Should Choose a Rotary Converter for Your Power Needs

In the realm of industrial power solutions, the choice of equipment can significantly impact operational efficiency and cost-effectiveness. Among the various options available, the rotary converter stands out as a preferred choice due to its unique ability to convert electrical power efficiently. According to a report by the International Energy Agency (IEA), the demand for efficient power conversion technologies has grown significantly, with businesses seeking to reduce energy loss and improve overall productivity. Rotary converters, known for their reliability and versatility, have become essential in various applications, from small workshops to large manufacturing plants.

Recent industry data highlight that rotary converters can achieve conversion efficiencies of up to 95%, which leads to substantial savings on energy costs. In an era where sustainability is paramount, the ability of rotary converters to operate under different loads while maintaining high levels of performance becomes even more crucial. Moreover, the growing trend of retrofitting older machinery with rotary converters for enhanced efficiency aligns with the industry's shift towards more sustainable practices. As organizations increasingly prioritize energy efficiency and reliability, the rotary converter emerges as a top contender to meet diverse power needs across multiple sectors.

Understanding Rotary Converters: An Overview

Rotary converters play a significant role in the efficiency and versatility of power supply systems. By converting alternating current (AC) to direct current (DC) and vice versa, they provide a crucial solution for various industrial applications, including electric motor drives and rail systems. According to a report by the International Energy Agency, integrating rotary converters can enhance energy efficiency by up to 30%, making them an increasingly attractive option for businesses looking to reduce operational costs.

When considering a rotary converter, it's important to understand the technology behind it. Unlike static converters, which can experience high harmonic distortion, rotary converters generate smoother power outputs that lead to less wear and tear on machinery. They typically feature a rotating element that provides an inherent power quality advantage, allowing for stable voltage and minimal fluctuations. This characteristic is particularly beneficial for industries requiring consistent performance, such as manufacturing and telecommunications.

Tips: When selecting a rotary converter, evaluate the load requirements carefully to ensure proper sizing and performance. Additionally, consider investing in models with higher efficiency ratings to maximize long-term savings. Regular maintenance checks can also extend the lifespan of your rotary converter, ensuring reliability and optimal operation.

Advantages of Rotary Converters for Power Supply

Rotary converters have emerged as a reliable solution for varied power supply needs, particularly in industrial and commercial applications. One of the primary advantages of rotary converters is their inherent ability to provide a stable and efficient power source. Industry reports indicate that rotary converters can achieve efficiencies of over 95%, which surpasses many static solutions available in the market. This high efficiency not only results in lower energy costs but also minimizes the carbon footprint of operations, making rotary converters an environmentally friendly choice.

Another significant benefit of rotary converters is their versatility in handling different types of electrical loads. They can seamlessly convert single-phase power to three-phase power, accommodating a diverse range of equipment and machinery. According to a 2022 study by the Electrical Engineering Association, systems utilizing rotary converters reported a 30% reduction in downtime compared to those relying on less flexible power supply methods. This adaptability is essential for industries that require uninterrupted power supply for essential operations, as it allows them to maintain productivity and reduce the risk of equipment failure.

Furthermore, rotary converters are known for their durability and low maintenance requirements. Many rotary converter systems can operate for decades with minimal upkeep, which significantly lowers the total cost of ownership over time. Statistics from a recent manufacturing industry report highlight that facilities using rotary converters experienced a 40% decrease in maintenance costs relative to alternative power solutions. Overall, the advantages of rotary converters make them an optimal choice for businesses seeking reliable, efficient, and adaptable power supply solutions.

Advantages of Rotary Converters for Power Supply

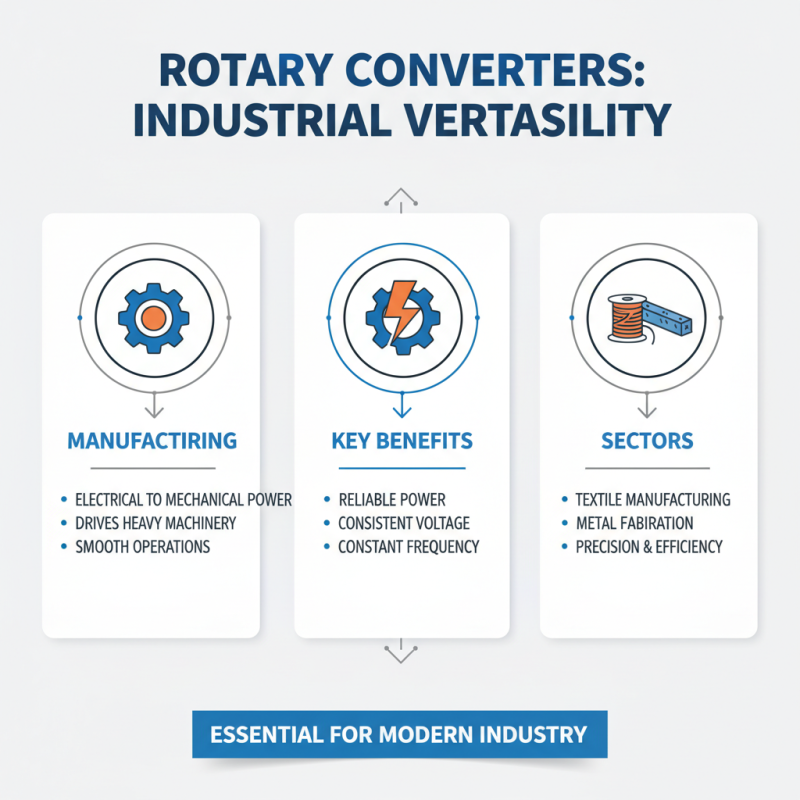

Applications of Rotary Converters in Various Industries

Rotary converters are versatile devices that play a crucial role across various industries. In manufacturing, they facilitate the conversion of electrical energy into mechanical power, essential for driving heavy machinery and ensuring smooth operations. The ability to provide reliable power at a consistent voltage and frequency makes rotary converters particularly valuable in sectors such as textile manufacturing and metal fabrication, where precision and efficiency are paramount.

In the realm of entertainment, rotary converters are used in film and audio production, ensuring that vintage equipment operates seamlessly with modern electrical systems. This integration is vital for preserving the authenticity of sounds and images while utilizing the latest technologies. Additionally, the renewable energy sector benefits from rotary converters, as they help convert wind or solar-generated power into usable forms of electricity, thus promoting sustainability.

**Tips:** When selecting a rotary converter, consider the total power requirement of your application to avoid under or overloading. Regular maintenance can extend the lifespan of your converter and improve overall efficiency. Lastly, ensure that the installation is executed by professionals to optimize performance and safety standards in your facility.

Comparing Rotary Converters with Other Power Solutions

When evaluating power solutions, rotary converters stand out for their efficiency and reliability when compared to other alternatives like static converters or inverters. Rotary converters operate on the principle of electromechanical transformation, which can provide a smooth and continuous power supply. This makes them an excellent choice for applications requiring stable output, such as machinery and industrial equipment, where fluctuations can cause significant issues.

Tips: When selecting a rotary converter, consider the total load required by your machinery. Ensure the converter you choose can handle peak load demands to avoid overloading, which could lead to performance issues.

In contrast, static converters may offer a more compact solution but can struggle with load variations, resulting in potential instability. Inverters, while effective for converting DC to AC, often add complexity to the system and may not provide the same level of durability. For businesses prioritizing longevity and minimal maintenance, rotary converters deliver reliability that can outweigh the initial investment costs.

Tips: Regular maintenance of your rotary converter can prolong its lifespan and enhance performance. Schedule routine checks to identify any wear and tear, ensuring your equipment operates efficiently.

Why You Should Choose a Rotary Converter for Your Power Needs

| Feature | Rotary Converter | Inverter | Generator |

|---|---|---|---|

| Power Quality | High | Moderate | Variable |

| Efficiency | 95% | 85% | 80% |

| Cost | Moderate Initial, Low Operating | Low Initial, High Operating | High Initial, Moderate Operating |

| Maintenance | Low | Moderate | High |

| Noise Level | Low | Moderate | High |

Maintenance and Efficiency Considerations for Rotary Converters

When considering the maintenance of rotary converters, it is essential to recognize their mechanical and electrical components' specific needs. Regular inspection of the rotating parts is crucial, as wear and tear can affect the converter's performance. Lubrication of bearings and components ensures smooth operation and prolongs the lifespan of the unit. Furthermore, checking electrical connections and ensuring there are no loose or corroded parts can prevent unexpected breakdowns, which could lead to costly downtime. Establishing a routine maintenance schedule allows users to address minor issues before they evolve into major problems, ensuring that the system remains reliable and efficient.

Efficiency is another critical consideration when using rotary converters. These systems are designed to convert electrical power with a high degree of efficiency, but this can diminish if not properly maintained. Factors such as overheating and dust accumulation can hinder performance. Keeping the environment around the rotary converter clean and ensuring proper ventilation can significantly improve efficiency. Additionally, monitoring load variations and ensuring the converter operates within its optimal range can enhance overall performance. By prioritizing maintenance and efficiency, users can maximize the benefits of rotary converters, ensuring they meet their power needs effectively.

Related Posts

-

2025 Top Rotary Phase Converter: The Ultimate Guide for Efficient Power Solutions

-

Exploring the Impact of Rotary Phase Converters on Industrial Growth at the 2025 China 138th Import and Export Fair

-

How to Effectively Utilize Frequency to Voltage Converters in Your Projects

-

Unlocking the Benefits of 3 Phase Power Converters: A Comprehensive Guide for Efficient Energy Use

-

How to Choose the Right Electronic Converter for Your Business Needs

-

10 Reasons Why Solid State Frequency Converters Are Revolutionizing Global Supply Chain Efficiency