How to Choose the Right VFD Controller for Your Industrial Applications

Choosing the right Variable Frequency Drive (VFD) controller is crucial for optimizing the performance and efficiency of industrial applications. As industries increasingly shift towards automated solutions, the demand for robust and versatile VFD controllers has surged. These controllers play a vital role in regulating the speed and torque of electric motors, thereby enhancing overall energy savings and operational control. However, selecting the appropriate VFD controller can be a daunting task, given the plethora of options available in the market.

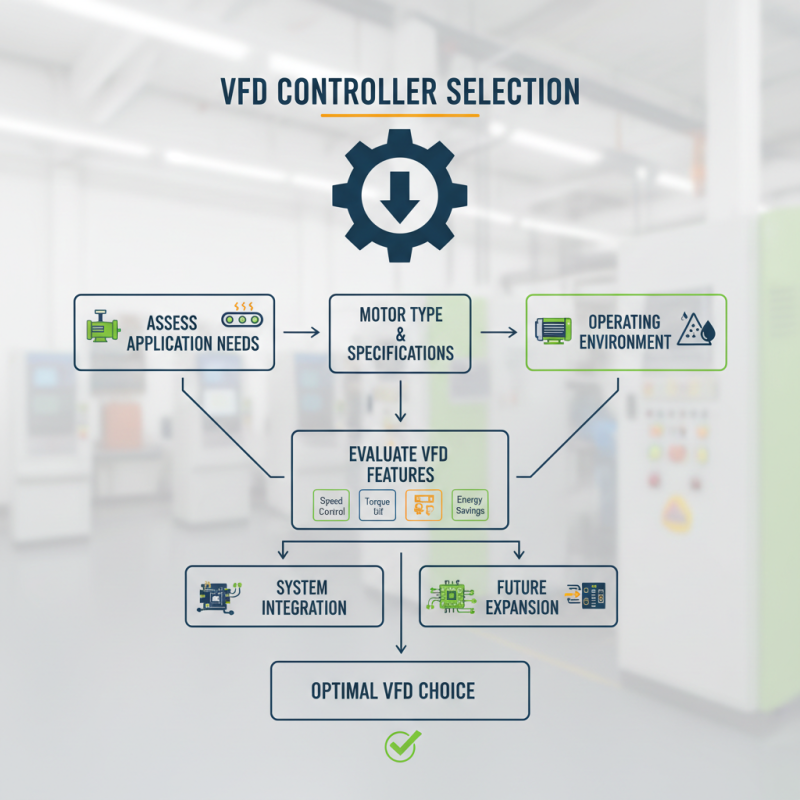

To make an informed decision, it's essential to consider several factors, including the specific requirements of your application, the type of motor being used, and the environment in which the VFD controller will operate. Whether it’s for pumps, conveyor systems, or HVAC applications, understanding the unique features and specifications of different VFD controllers is key to achieving optimal performance. Additionally, implementation and integration into existing systems should also be assessed to ensure seamless operation. By carefully evaluating these aspects, you can choose a VFD controller that not only meets your current needs but also provides the flexibility for future expansion and upgrades.

Understanding the Basics of Variable Frequency Drives (VFD)

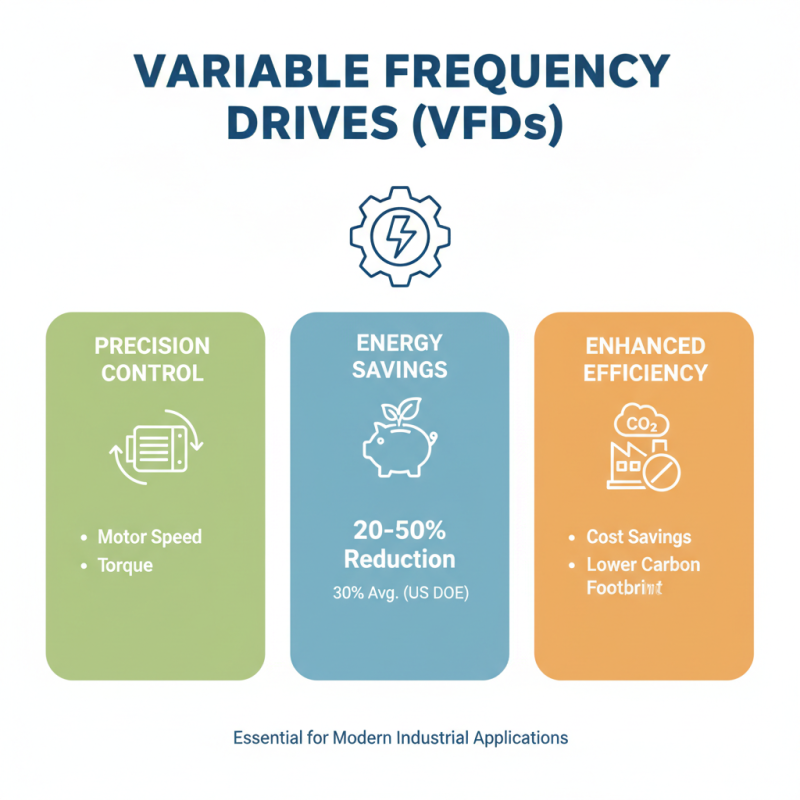

Variable Frequency Drives (VFDs) are essential components in modern industrial applications, allowing for precise control of motor speed and torque. By adjusting the frequency and voltage supplied to an electric motor, VFDs enable energy savings of 20-50%, significantly enhancing operational efficiency. According to a report by the U.S. Department of Energy, industrial facilities that implement VFD technology can reduce energy consumption by as much as 30%, leading to substantial cost savings and a lower carbon footprint.

Understanding the basic principles of VFD technology is crucial for selecting the appropriate controller for specific applications. A VFD operates by converting incoming AC voltage into DC voltage and then back into variable frequency AC voltage, facilitating control over the motor's speed. The key parameters to consider include the power rating, input power supply, and the type of motor used in your system. Industry studies suggest that applications requiring precise speed control, such as conveyors, pumps, and fans, particularly benefit from VFDs, with performance enhancements often exceeding expectations when correctly implemented.

As the industrial sector increasingly seeks sustainable and efficient solutions, the importance of VFDs cannot be overstated. The global VFD market is projected to grow at a CAGR of 8.3% from 2021 to 2028, driven by the demand for energy-efficient technologies and the growing emphasis on automation across various industries. Understanding the fundamentals of VFDs is not only beneficial for optimizing performance but also crucial for staying competitive in a rapidly evolving industrial landscape.

Identifying Your Industrial Application Requirements

When selecting the right Variable Frequency Drive (VFD) controller for industrial applications, identifying specific application requirements is crucial. Key factors to consider include load type, control method, and operational environment. According to a report by Grand View Research, the global VFD market is anticipated to reach USD 13.81 billion by 2025, indicating a growing demand for tailored solutions across various industries. Understanding operational goals such as energy efficiency and process automation will guide the functionality you require in a VFD, ensuring optimal performance and longevity of equipment.

It’s essential to conduct a thorough assessment of your application needs. For instance, whether your system involves variable torque loads like fans and pumps or constant torque applications such as conveyors can significantly influence VFD selection. Additionally, parameters such as the desired speed range and power ratings play a pivotal role. A report from MarketsandMarkets highlights that energy savings of 20-50% can be achieved by using VFDs, making it critical to specify your energy consumption objectives when making decisions.

Tips: Ensure your VFD selection aligns with your system’s electrical requirements, including voltage and current ratings. Furthermore, consider potential future demands to avoid needing a replacement as operational needs evolve. Regularly revisiting your application requirements can assist in optimizing performance and maintaining efficiency over time.

Evaluating Types of VFD Controllers Available

When selecting a Variable Frequency Drive (VFD) controller for industrial applications, understanding the various types available is crucial for optimal performance and efficiency. VFDs can be categorized mainly into two types: voltage-source inverters (VSI) and current-source inverters (CSI). Voltage-source inverters are commonly used due to their simpler operation and compatibility with a wide range of motor types. They provide good performance for most applications, especially in industries requiring precise motor control.

On the other hand, current-source inverters are less common but are suitable for specific applications where high torque at low speeds is necessary. These VFDs manage high power levels and are often employed in heavy-duty industrial settings. Additionally, there are specialized VFDs designed for particular environments, such as those with high humidity, extreme temperatures, or explosive atmospheres. Evaluating your application’s environmental conditions and operational demands will help in selecting the right type of VFD controller.

Moreover, some VFDs come equipped with advanced features such as built-in communication protocols and energy-saving functionalities. Assessing your system's requirements for automation and integration can further guide the selection process. In conclusion, understanding the variety of VFD controllers and their specific applications is essential in ensuring that the chosen controller meets both the operational and environmental needs of your industrial setup.

How to Choose the Right VFD Controller for Your Industrial Applications - Evaluating Types of VFD Controllers Available

| VFD Type | Description | Advantages | Common Applications |

|---|---|---|---|

| V/F Control | Voltage/Frequency Control, basic control method. | Simple implementation, inexpensive. | Fans, pumps, basic conveyors. |

| Sensorless Vector Control | No sensors required; uses algorithms for torque control. | Better performance at low speeds, good efficiency. | Cranes, extruders, textile machinery. |

| Closed-loop Vector Control | Uses feedback from sensors for precise control. | Very precise torque control, high performance. | Robotics, CNC machines, high-performance applications. |

| Servo Drives | Designed for motion control with high accuracy. | High speed, high accuracy, feedback control. | Industrial robots, high-speed conveyor systems. |

Key Features to Consider When Selecting a VFD

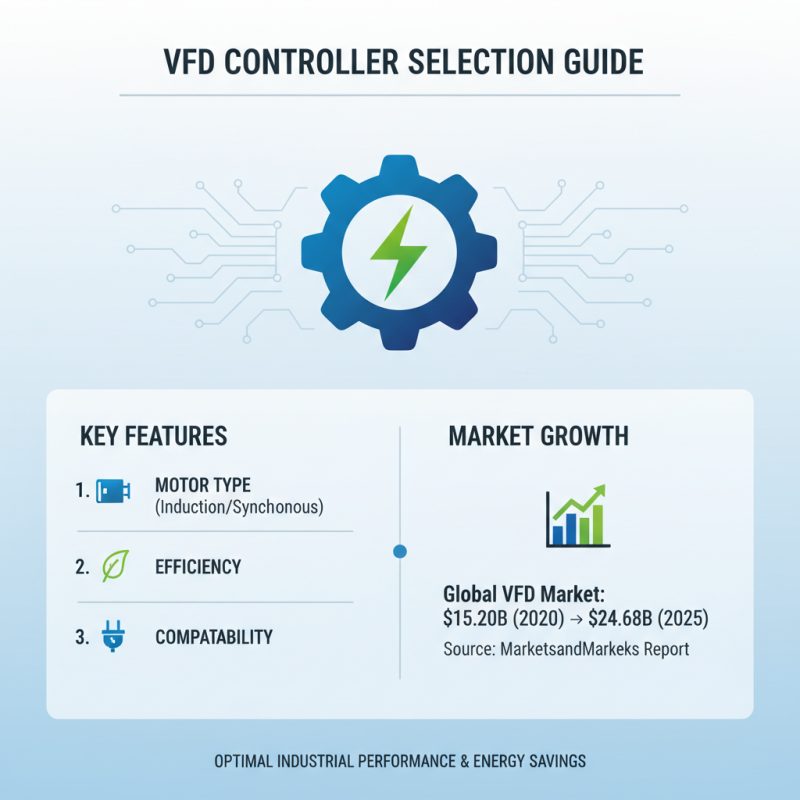

When selecting a Variable Frequency Drive (VFD) controller for industrial applications, several critical features must be taken into account to ensure optimal performance and efficiency. One of the foremost considerations is the motor type being used. Different VFDs are designed to work with specific motor types, such as induction motors or synchronous motors. According to a report by MarketsandMarkets, the global VFD market is projected to grow from USD 15.20 billion in 2020 to USD 24.68 billion by 2025, reflecting the increasing demand for energy-efficient solutions in various industrial sectors.

Another essential feature to evaluate is the control method employed by the VFD. Common control methods include V/f control, vector control, and direct torque control. Each method has its advantages and is suitable for different applications. For example, vector control provides high precision and better dynamic performance, which is crucial in applications requiring speed and torque control. Additionally, the selection of a VFD should consider environment parameters such as ambient temperature and humidity, as these can affect the drive's performance and lifespan. The International Energy Agency (IEA) has emphasized that optimal energy management, facilitated by the correct selection of VFDs, can lead to energy savings of up to 30% in industrial systems.

Finally, an assessment of the user interface and programmable features is vital for ensuring ease of use and adaptability. A good VFD should offer intuitive programming options, data logging capabilities, and connectivity for remote monitoring. Industry reports highlight that user-friendly interfaces contribute to lower operational costs and less downtime, further emphasizing the importance of selecting the right VFD controller tailored to specific industrial needs.

Assessing Compatibility with Existing Equipment and Systems

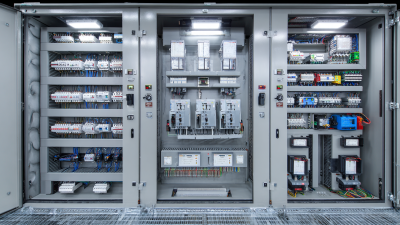

When selecting a Variable Frequency Drive (VFD) controller for your industrial applications, assessing compatibility with existing equipment and systems is crucial. Start by evaluating the specifications of your current machinery. This includes understanding their voltage, current ratings, and power requirements. A thorough examination ensures that the VFD will operate effectively within the parameters of your existing setup without the risk of damage or inefficiency.

Furthermore, consider the communication protocols used by your current systems. The VFD must seamlessly integrate with controllers and monitoring systems to provide feedback and ensure optimal performance. Additionally, it is vital to account for the mechanical aspects, such as the type of motors in use. Not all motors will perform well with every VFD, so checking the compatibility of motor types, whether they are induction, synchronous, or servo motors, is essential. By taking these factors into account, you can select a VFD that not only fits but enhances your operational efficiency.

VFD Controller Compatibility Assessment

Related Posts

-

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency

-

Comprehensive Guide to Choosing the Right Voltage Frequency Converter for Optimal Performance

-

How to Choose the Right Solid State Phase Converter for Your Business Needs

-

How to Choose the Right Voltage Frequency Converter for Your Needs

-

Unlocking Efficiency: How 3 Phase Frequency Converters Revolutionize Industrial Operations

-

Top Single to Three Phase Converter Solutions for 2025 You Need to Know