How to Choose the Best 60hz to 50hz Frequency Converter for Your Needs

When dealing with varying electrical systems around the world, understanding the importance of frequency converters becomes crucial. One common scenario involves the need to convert electrical frequencies from 60Hz to 50Hz, emphasizing the role of a 60Hz to 50Hz frequency converter. Whether for personal use or industrial applications, selecting the right converter can significantly impact the efficiency and functionality of electrical devices. With the global market witnessing a rise in the usage of equipment designed for different frequency standards, knowing how to choose the best frequency converter is essential for ensuring compatibility and performance.

In this exploration, we will delve into the key factors to consider when selecting a 60Hz to 50Hz frequency converter. Factors such as power rating, size, and ease of installation will be discussed to provide a comprehensive guide for both novice and experienced users. Furthermore, we will highlight the common applications of these converters and the benefits they offer in various settings. Ultimately, making an informed decision in choosing the best 60Hz to 50Hz frequency converter will enable users to maximize their equipment’s potential while ensuring safe and reliable operation.

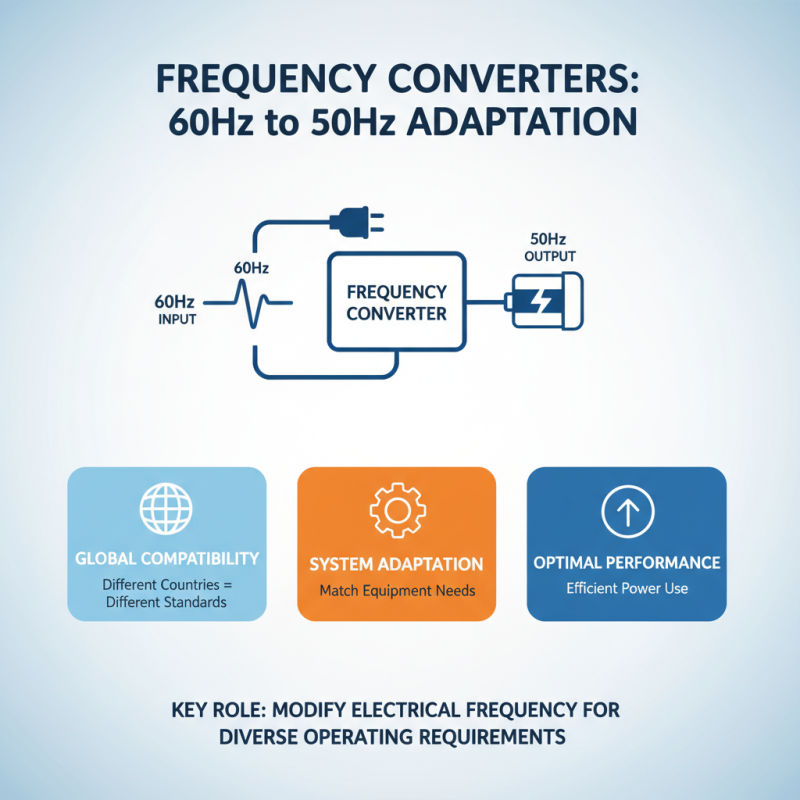

Understanding the Basics of Frequency Converters: 60Hz to 50Hz

Frequency converters play a crucial role in adapting electrical systems to different operating requirements, particularly when it comes to converting 60Hz power supply to 50Hz. Understanding the basics of frequency converters is essential for selecting the right one for your needs. A frequency converter modifies the frequency of the electrical output to match the requirements of the equipment being powered. This is particularly important in international contexts where electrical standards may vary between countries.

When considering a 60Hz to 50Hz frequency converter, it's important to recognize the two primary types: static and rotary converters. Static converters use electronic components to adjust the frequency, offering a compact and efficient solution for smaller applications. On the other hand, rotary converters, which involve mechanical rotating parts, are typically more robust and suitable for larger industrial systems. Each type has its advantages and limitations, so assessing your specific needs, including power output, efficiency, and potential load variations, is crucial in making the right choice.

Additionally, pay attention to the converter's capacity and features. Ensure the converter can handle the maximum load you expect, and consider models with built-in protections against overvoltage, overheating, and surges. Shortlisting converters with user-friendly interfaces and monitoring capabilities can improve usability and performance, making the system more reliable in the long run. By understanding these fundamental aspects, you can better navigate your options and select the most appropriate frequency converter for your application.

Key Factors to Consider When Choosing a Frequency Converter

When choosing the best 60Hz to 50Hz frequency converter for your needs, several key factors should be considered to ensure optimal performance and suitability. Firstly, assess the power requirements of your equipment. It's important to evaluate the wattage and the compatibility of the converter with your devices. A converter must be able to handle the total load of the equipment without overheating or malfunctioning, ensuring longevity and efficiency during operation.

Another critical factor is the converter's efficiency and quality. Look for converters that offer high efficiency rates to save on energy costs and reduce environmental impact. The build quality and reliability of the device are also paramount as you want a unit that can withstand prolonged use without failure. Consider factors such as cooling systems and fail-safe features that can provide additional peace of mind during operation.

Tips: Always consult the specification sheets for both your equipment and the converter. This helps to understand the necessary input and output parameters. Additionally, read customer reviews and feedback about the performance and reliability of the converters you are considering to make a more informed decision. Finally, look for converters that come with a warranty, as this indicates confidence in the product's reliability and may save you from unforeseen costs in the future.

Types of Frequency Converters: Which One is Right for You?

When selecting the right frequency converter, understanding the different types available is crucial. Frequency converters generally come in two main varieties: rotary converters and static converters. Rotary converters utilize mechanical components to convert power and are ideal for applications requiring high reliability and performance over extended periods. They tend to be suited for larger loads and offer the advantage of being able to handle both voltage and frequency conversion simultaneously.

On the other hand, static frequency converters are more compact and typically involve electronic components. These are better for smaller applications where space is limited and where the load may fluctuate. Static converters are often more cost-effective and are easier to maintain, making them a popular choice for consumer appliances, industrial machines, and renewable energy systems. Understanding the specific requirements of your application will guide you in choosing the most appropriate type, ensuring that your frequency converter meets your operational needs efficiently.

Evaluating Efficiency and Performance of 60Hz to 50Hz Converters

When selecting a 60Hz to 50Hz frequency converter, the efficiency and performance of the device are critical factors to consider. A recent industry report from the International Electrotechnical Commission (IEC) indicates that efficiency levels for modern converters typically range between 85% to 95%. This efficiency can significantly impact the operational costs for businesses, especially in energy-intensive industries. Therefore, it's essential to assess the conversion efficiency, as even a 5% increase can lead to substantial savings over time, particularly in large-scale operations where multiple units may be in use.

In terms of performance, the ability of a frequency converter to maintain voltage stability and minimize harmonic distortion is crucial. According to a report by the Institute of Electrical and Electronics Engineers (IEEE), converters that employ advanced pulse-width modulation techniques can reduce harmonic distortion to levels below the 5% THD (Total Harmonic Distortion) threshold, thereby ensuring better performance for sensitive equipment. Furthermore, the reliability of the converter under varying loads is another key performance metric. Data suggests that devices designed with superior thermal management systems can operate efficiently across a wider range of temperatures, enhancing their lifespan and reliability in diverse environments. Thus, evaluating these factors thoroughly can lead to a more informed decision that aligns the frequency converter’s capabilities with specific operational needs.

Installation and Maintenance Tips for Frequency Converters

When installing a frequency converter, it's essential to follow specific guidelines to ensure optimal performance and longevity. First, carefully select a location that is cool, dry, and well-ventilated to prevent overheating. Ensure that the device is mounted securely and that all electrical connections are made according to the manufacturer's specifications. It’s crucial to use appropriate cables and connectors to handle the converter's electrical load, as improper connections can lead to significant operational issues.

Regular maintenance of frequency converters significantly prolongs their lifespan and efficiency. Schedule periodic inspections to check for signs of wear, such as frayed wires or loose connections. Cleaning the unit to remove dust and debris is also essential, as buildup can impede its operation. Make sure to monitor input and output voltages closely to ensure they stay within the recommended ranges. Additionally, keeping a log of maintenance activities can help identify patterns that might indicate the need for repair or replacement, ultimately ensuring that the frequency converter operates at peak efficiency throughout its service life.

How to Choose the Best 60hz to 50hz Frequency Converter for Your Needs - Installation and Maintenance Tips for Frequency Converters

| Feature | Description | Importance | Maintenance Tips |

|---|---|---|---|

| Power Rating | Power capacity required for your equipment | High | Check ratings regularly to ensure efficiency |

| Input Voltage | Voltage levels of your power source | Medium | Verify input voltage compatibility during installation |

| Output Voltage | Required voltage level for your equipment | High | Adjust settings as needed to match equipment requirements |

| Size and Weight | Physical dimensions and weight of the converter | Medium | Ensure adequate space for installation |

| Cooling Mechanism | Method of heat dissipation used | High | Ensure vents are unobstructed and clean |

| Protection Features | Built-in safeguards against overloads and faults | High | Test protection features periodically |

Related Posts

-

Understanding the Transition: How a 60 Hz to 50 Hz Frequency Converter Can Enhance Energy Efficiency in Industrial Applications

-

Unveiling New Innovations: 400Hz Frequency Converters at the 138th Canton Fair 2025

-

The Future of Solid State Frequency Converters Redefining Power Management

-

Understanding the Benefits of Using a 400hz to 60hz Converter for Your Electrical Systems

-

Unlocking Efficiency: How 3 Phase Frequency Converters Revolutionize Industrial Operations

-

Ultimate Guide to 400Hz to 60Hz Converters: Top Picks for 2025