How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs

In today's competitive industrial landscape, the efficiency of machinery and electrical systems is paramount for business success. One crucial component that often gets overlooked is the converter used to power three-phase equipment in single-phase environments. The implementation of a single phase to 3 phase converter can significantly enhance operational performance, enabling businesses to leverage the benefits of three-phase power, which is known for its smoother operation and efficiency.

According to a report by the Electric Power Research Institute, up to 30% of industrial facilities still rely on single-phase power, potentially limiting their productivity and increasing operational costs. As businesses seek to optimize their processes and reduce energy consumption, choosing the right single phase to 3 phase converter becomes essential. This guide aims to provide valuable insights and considerations for organizations looking to make this critical transition.

Understanding the Basics of Single Phase and Three Phase Power Systems

Understanding the basics of single phase and three phase power systems is crucial for businesses looking to optimize their energy consumption and performance. Single phase power systems supply electricity via two wires, making them suitable for smaller loads, typically below 10 kW. According to the U.S. Energy Information Administration (EIA), approximately 80% of residential and light commercial facilities use single phase systems due to their lower installation costs and simplicity. However, as operational demands increase, transitioning to a three phase system, which utilizes three wires providing power in a more consistent and efficient manner, can often deliver significant benefits.

Three phase power systems are ideal for industrial and heavy commercial applications, where power needs exceed 10 kW. They provide a more stable power supply, reducing the flickering and voltage drops that can occur with single phase systems. A report from the National Renewable Energy Laboratory (NREL) highlights that three phase systems can increase electrical efficiency by nearly 15% when compared to single phase options. Furthermore, businesses can reduce operational costs by utilizing three phase motors, which are not only more efficient but also have a longer lifespan. Understanding these fundamental differences helps businesses make informed decisions regarding energy needs and ultimately improving their bottom line.

Identifying Your Business Power Needs and Requirements

When selecting a single phase to 3 phase converter for your business, understanding your power needs is crucial. According to the U.S. Department of Energy, around 70% of industrial applications require three-phase power to operate efficiently. With that in mind, businesses should begin by evaluating the types of machinery and equipment they use, as different machines may have varying power requirements. For instance, equipment such as motors and compressors typically perform better on three-phase power due to their increased efficiency and lower electricity costs, which can be up to 30% less than single-phase alternatives.

Additionally, it’s essential to consider the total load your business will place on the converter. The average commercial facility experiences an electricity demand of about 1.5 kW to 5 kW per workstation. By anticipating future growth or additional machinery, businesses can select a converter that not only meets current requirements but is also scalable for upcoming needs. Reports suggest that properly sizing the converter can lead to significant savings, with companies reporting up to a 20% reduction in operational costs when power needs are accurately matched to the converter’s capacity. By carefully analyzing these aspects, businesses can make informed decisions that optimize performance and efficiency.

Key Factors to Consider When Choosing a Converter

When selecting the right single phase to three phase converter for your business, there are several key factors to consider. First, it's essential to assess your power requirements. Determine the total kilowatt (kW) rating of the equipment you will be operating, as this will help you choose a converter that can handle the necessary load without compromising performance. Overloading a converter can lead to inefficiencies and potential damage to both the converter and your machinery.

Another critical factor is the type of converter suitable for your applications. There are various types of converters, including rotary and static converters. Rotary converters are ideal for heavy-duty applications and provide a more stable voltage supply, while static converters are typically more compact and economical, suited for lighter loads. Evaluate your specific needs and choose a converter that aligns with the operational demands of your business.

Additionally, consider the converter's efficiency and reliability. Opt for models with a good track record and warranty, ensuring that you receive support should any issues arise. Researching customer reviews and seeking professional advice can also help you make an informed choice, ensuring that your investment in a converter will enhance your business operations effectively.

How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs - Key Factors to Consider When Choosing a Converter

| Factor | Details | Importance | Recommended Specifications |

|---|---|---|---|

| Power Requirements | Assess the total power needed for your machines. | High | Converter should match or exceed the total HP rating of the equipment. |

| Input Voltage | Verify the input voltage your operation uses. | High | Ensure compatibility with standard voltage inputs (e.g., 120V, 220V). |

| Load Type | Consider the nature of the load (inductive or resistive). | Medium | Inductive loads may require special converter features. |

| Conversion Type | Choose between rotary or static converters. | Medium | Rotary for high power; static for compact applications. |

| Budget | Define your budget for the converters. | High | Look for converters that provide the best value within your budget. |

| Installation Requirements | Check for the ease of installation and space considerations. | Medium | Select a converter that fits your operational layout and is easy to install. |

Types of Single Phase to Three Phase Converters Explained

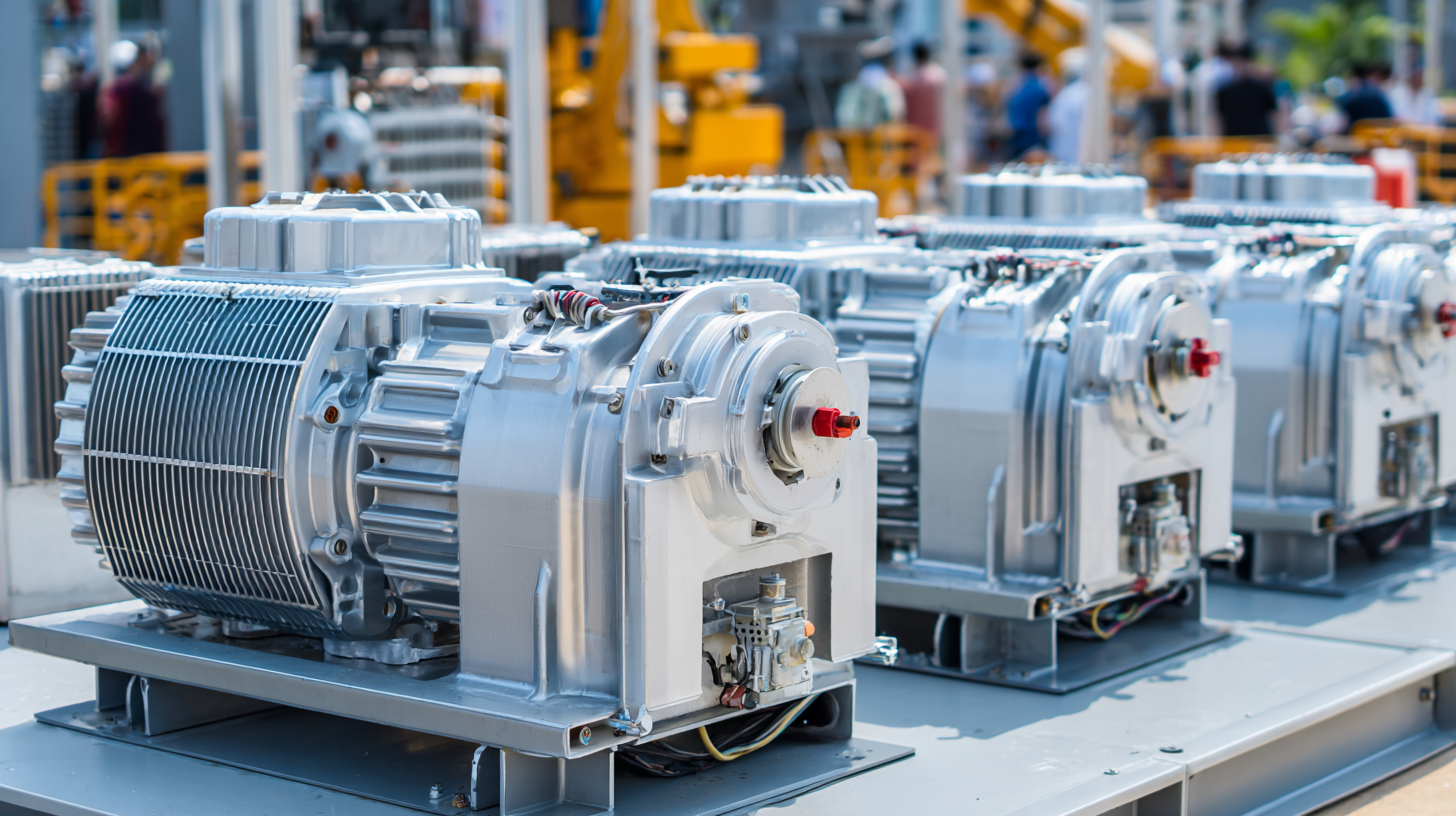

When it comes to powering three-phase machinery using single-phase power sources, understanding the different types of single-phase to three-phase converters is crucial for your business. The most common types include rotary converters, static converters, and digital phase converters. Each type has its unique advantages and suitability for various applications.

Rotary converters are known for their ability to provide a robust solution for heavy-duty machinery. They consist of an electric motor and a generator, allowing them to handle significant loads with consistency. Static converters, on the other hand, are more compact and offer an efficient way to power lighter loads. These converters use electronic circuitry to create a three-phase output but may not provide the same performance as rotary converters under heavy loads. Lastly, digital phase converters are a modern solution that utilizes microprocessor technology to optimize performance and efficiency, making them ideal for variable load conditions often found in manufacturing settings.

Choosing the right converter depends on your operational demands and the nature of the devices you intend to power. By comparing these types, you can make an informed decision that balances efficiency, cost, and the specific power requirements of your business.

Tips for Installation and Maintenance of Your Converter

When installing a single-phase to three-phase converter, proper installation and maintenance are crucial for ensuring optimal performance and longevity. According to the Electric Power Research Institute (EPRI), converters, when correctly installed, can increase energy efficiency by up to 30%. To achieve this, it's essential to select a location that minimizes exposure to moisture and contaminants, ensuring the converter operates under ideal conditions. Professionals recommend that installations be carried out with a qualified electrician, as improper wiring can lead to equipment damage and safety hazards.

Once installed, regular maintenance is key to extending the lifespan of your converter. The National Electrical Manufacturers Association (NEMA) emphasizes the importance of scheduled inspections at least twice a year. These inspections should include checking connections for wear and tear, ensuring all components are free from dust and debris, and verifying that cooling systems are functioning properly. Adhering to these maintenance practices not only prevents downtime but can also save businesses as much as 20% in repair costs over time. By investing in proper installation and diligent upkeep, businesses can maximize the benefits of their converters while minimizing operational disruptions.

Power Conversion Efficiency of Single Phase to 3 Phase Converters

Related Posts

-

How to Seamlessly Upgrade from Single Phase to Three Phase Power Systems

-

Mastering the Basics: A Step-by-Step Guide to Using 3 Phase Frequency Converters

-

The Future of Solid State Frequency Converters Redefining Power Management

-

Ultimate Guide to Selecting the Right Power Converter for Optimal Efficiency

-

10 Reasons Why Solid State Frequency Converters Are Revolutionizing Global Supply Chain Efficiency

-

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency