How to Choose the Right Three Phase Converter for Optimal Efficiency and Performance

Selecting the appropriate three phase converter is crucial for maximizing operational efficiency and performance in industrial applications. According to a recent report by the International Energy Agency (IEA), three phase systems provide substantial benefits, such as reduced energy losses and improved load handling capabilities compared to single-phase systems. In fact, manufacturers that switch to three phase converters can experience up to 30% increase in energy efficiency, significantly lowering operational costs over time. As industries increasingly seek to enhance productivity while maintaining sustainability, understanding the nuances of three phase converters becomes imperative. This guide will provide insights into how to select the right converter, factoring in considerations such as power requirements, installation environment, and compatibility with existing equipment, ensuring optimal efficiency and performance in your operations.

Understanding the Basics of Three Phase Converters and Their Types

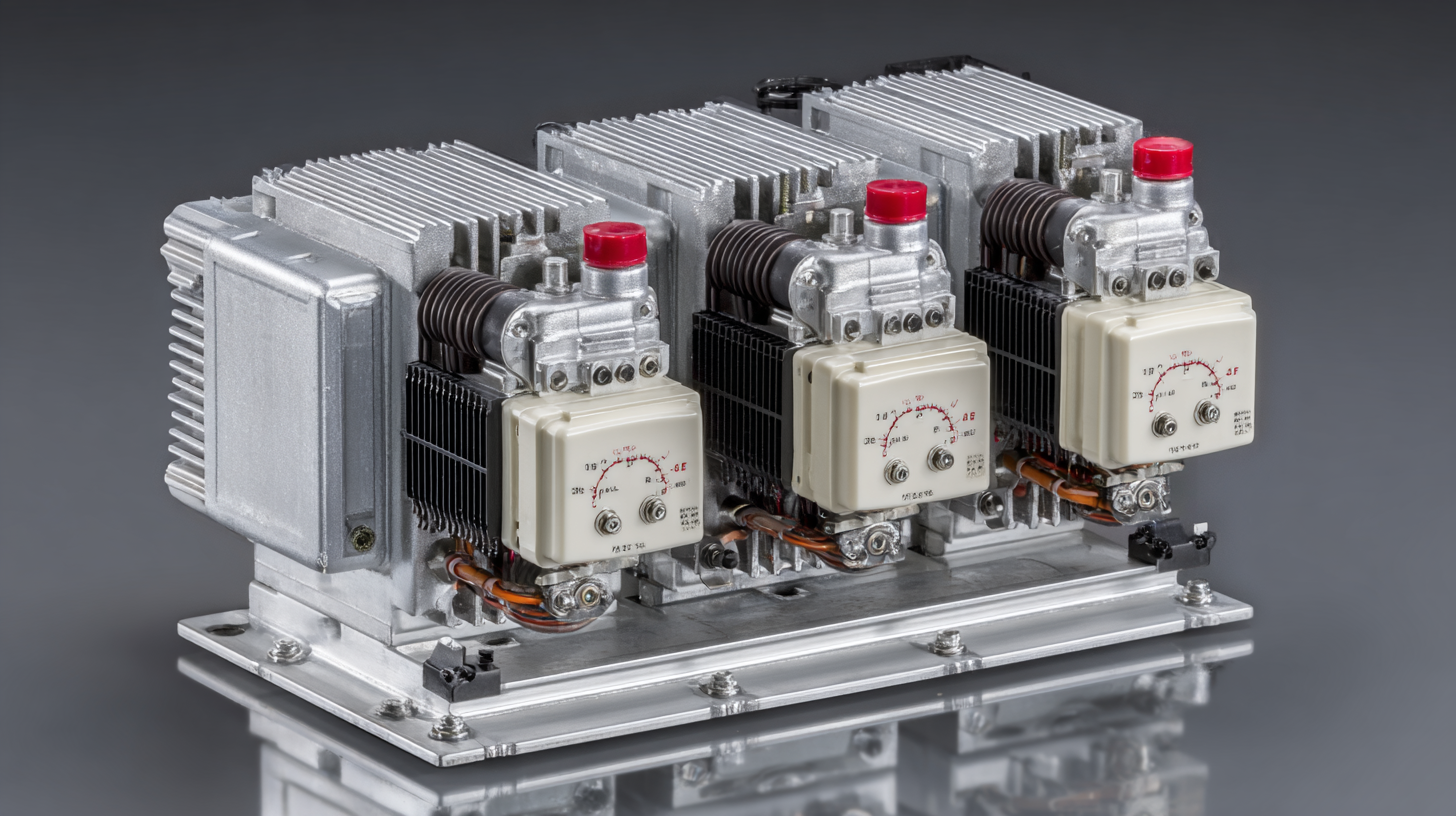

Three-phase converters are essential devices that facilitate the conversion of single-phase power to three-phase power, which is crucial for running industrial equipment and machinery. Understanding the basics of three-phase converters begins with recognizing the types available: rotary converters, static converters, and digital converters. Rotary converters, often used in applications requiring high starting torque, utilize a rotating machine to convert power and provide a smooth output. In contrast, static converters use power electronics to achieve conversion without moving parts, making them suitable for lighter applications where efficiency and space are key considerations.

The choice of converter type depends largely on the specific application and operational requirements. For instance, rotary converters are typically preferred in heavy-duty applications due to their robust design and ability to handle larger loads, while static converters are ideal for smaller, less demanding tasks where cost-efficiency and ease of installation are paramount. Additionally, digital converters are gaining popularity for their advanced features, including monitoring capabilities and improved energy efficiency. By understanding these variations, users can select the optimal type of three-phase converter, ensuring high performance and efficiency in their specific applications.

How to Choose the Right Three Phase Converter for Optimal Efficiency and Performance

| Converter Type | Efficiency (%) | Cost ($) | Best Applications |

|---|---|---|---|

| Rotary Converter | 95 | 2000 | Industrial Motors, Large Equipment |

| Static Converter | 85 | 600 | Small Equipment, Hobby Uses |

| Digital Phase Converter | 98 | 1500 | Sensitive Equipment, CNC Machines |

| Hybrid Converter | 92 | 1200 | General Purpose, Versatile Uses |

Key Factors Influencing Efficiency in Three Phase Converter Selection

When selecting a three-phase converter, several key factors can significantly influence efficiency and performance. One crucial consideration is the type of load being powered. Inductive loads, such as motors, typically require different converter characteristics than resistive loads. According to a report by the Electrical Power Research Institute (EPRI), converters designed with enhanced voltage regulation help optimize performance for inductive loads, thereby minimizing energy losses and improving overall efficiency by up to 10%.

Another important factor is the converter's design topology. Different designs, including rotary and static converters, offer varying efficiency levels. Research indicates that static converters can achieve efficiency ratings exceeding 95% in optimal circumstances, which can lead to substantial cost savings over time. It's essential to evaluate both the initial investment and the long-term operational costs associated with each type of converter to determine the best fit for specific applications.

**Tips:**

1. Always analyze the motor's characteristics and load type to select the appropriate converter that minimizes energy loss.

2. Consider investing in advanced models that include features like automatic voltage regulation to enhance performance.

3. Regular maintenance and monitoring can ensure continued efficiency, helping to avoid unexpected downtimes and costly repairs.

Evaluating Power Requirements: Sizing Your Three Phase Converter Correctly

When selecting a three-phase converter for optimal efficiency and performance, understanding your power requirements is crucial. Sizing your converter correctly involves assessing the load your application will demand. This includes evaluating the voltage and current ratings needed for your specific operational needs. In particular, for electric vehicles, where energy consumption and driving range are critical, precise calculations become even more important. Utilizing performance analysis techniques can help determine how different configurations of converters will affect battery efficiency.

Tips: When sizing your converter, consider the maximum load you expect to use. A common practice is to select a converter with a capacity at least 20% higher than your maximum anticipated load. This safeguard ensures that the converter operates within its optimal range, preventing overheating and prolonging its lifespan.

Additionally, keep an eye on the type of load your converter needs to handle. Reactive loads, such as those found in photovoltaic systems, could lead to inefficiencies if not managed correctly. Employing control strategies for reactive power management can improve performance, especially under fluctuating conditions. Proper sizing and management of your three-phase converter will ultimately enhance your system's reliability and efficiency.

Three Phase Converter Power Requirements

Analyzing the Impact of Load Characteristics on Converter Performance

When selecting a three-phase converter, understanding the impact of load characteristics is crucial for maximizing efficiency and performance. Different types of loads—whether they be resistive, inductive, or capacitive—exert varying demands on the converter. For instance, inductive loads, such as motors, create a phase difference between voltage and current, which can lead to significant energy losses if the converter is not optimized. According to a report by the IEEE, improper matching of converters with motor loads can result in efficiency drops of up to 20%, highlighting the necessity of accurate load analysis.

Moreover, the load's power factor plays an essential role in converter selection. A low power factor indicates higher reactive power demand, which can strain converters, causing overheating and reducing their operational lifespan. A study from the Electrical Engineering Research Institute indicated that enhancing the power factor by just 0.5 can improve energy efficiency by approximately 10%. Thus, a thorough assessment of load characteristics—encompassing power type, phase, and nature—should guide the choice of a three-phase converter, ensuring that it meets the specific demands of the application and operates at optimal efficiency.

Comparing Different Conversion Technologies for Optimal Application Suitability

When selecting the right three-phase converter, understanding the various conversion technologies is crucial for achieving optimal application suitability. The most common types include rotary converters, static converters, and digital converters, each offering unique advantages.

Rotary converters are renowned for their durability and capacity to handle varying loads effectively. They are ideal for heavy machinery and industrial applications but can be more expensive and require regular maintenance.

Rotary converters are renowned for their durability and capacity to handle varying loads effectively. They are ideal for heavy machinery and industrial applications but can be more expensive and require regular maintenance.

Static converters, on the other hand, are compact and efficient, making them suitable for smaller applications where space is a concern. They work well for equipment like fans and pumps but may not sustain high-load situations over extended periods.

Digital converters represent the latest innovation, providing excellent versatility and efficiency. They can adapt to varying electrical loads and improve performance while minimizing energy losses, making them an excellent choice for modern facilities.

Tips:

- Assess your specific application needs to determine the required power output and load characteristics before choosing a converter type.

- Consider maintenance costs and the physical space available for installation in your operational environment. Choosing a technology that aligns with these factors can enhance overall efficiency and longevity of the converter.

Related Posts

-

How to Choose the Right Solid State Phase Converter for Your Business Needs

-

Ultimate Guide to Selecting the Right Power Converter for Optimal Efficiency

-

The Future of Solid State Frequency Converters Redefining Power Management

-

10 Reasons Why Solid State Frequency Converters Are Revolutionizing Global Supply Chain Efficiency

-

Comprehensive Guide to Choosing the Right Voltage Frequency Converter for Optimal Performance

-

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency