5 Essential Facts About 50hz to 60hz Frequency Converters You Should Know

The transition from 50Hz to 60Hz frequency conversion technology is becoming increasingly vital as global industries seek to optimize their power systems and enhance energy efficiency. According to a report from the International Electrotechnical Commission (IEC), nearly 70% of the world's electrical systems operate at either 50Hz or 60Hz, making the 50Hz to 60Hz frequency converter an essential component for powering devices and machinery designed for a different frequency. In regions where these two standards are predominant, such as Europe and North America, the demand for frequency converters is projected to grow by approximately 8% annually through 2025, driven by increased industrialization and the need for renewable energy integration. Understanding the intricacies and applications of 50Hz to 60Hz frequency converters can significantly impact system reliability and performance, and knowing the key facts about these devices is crucial for engineers, manufacturers, and facility managers alike.

Key Differences Between 50Hz and 60Hz Power Systems and Their Impact on Frequency Converters

When considering the differences between 50Hz and 60Hz power systems, it is essential to recognize how these frequencies affect the performance and design of frequency converters. In regions where 50Hz is standard, such as Europe and parts of Asia, electrical appliances and industrial machines are optimized for this frequency. Conversely, North America predominantly operates at 60Hz, leading to a different set of specifications and performance expectations for devices functioning within these systems. The fundamental technical differences include variations in motor speed, efficiency, and overall load characteristics, which can significantly affect equipment compatibility.

Frequency converters serve to bridge the gap between these two power systems, allowing devices designed for one frequency to operate in an environment with another. However, the conversion process must account for efficiency losses, heat generation, and potential harmonic distortions, which can vary depending on whether the converter is stepping up or down the frequency. Understanding these differences is crucial for industries that rely on international operations and need reliable equipment performance across diverse electrical grids.

5 Essential Facts About 50Hz to 60Hz Frequency Converters

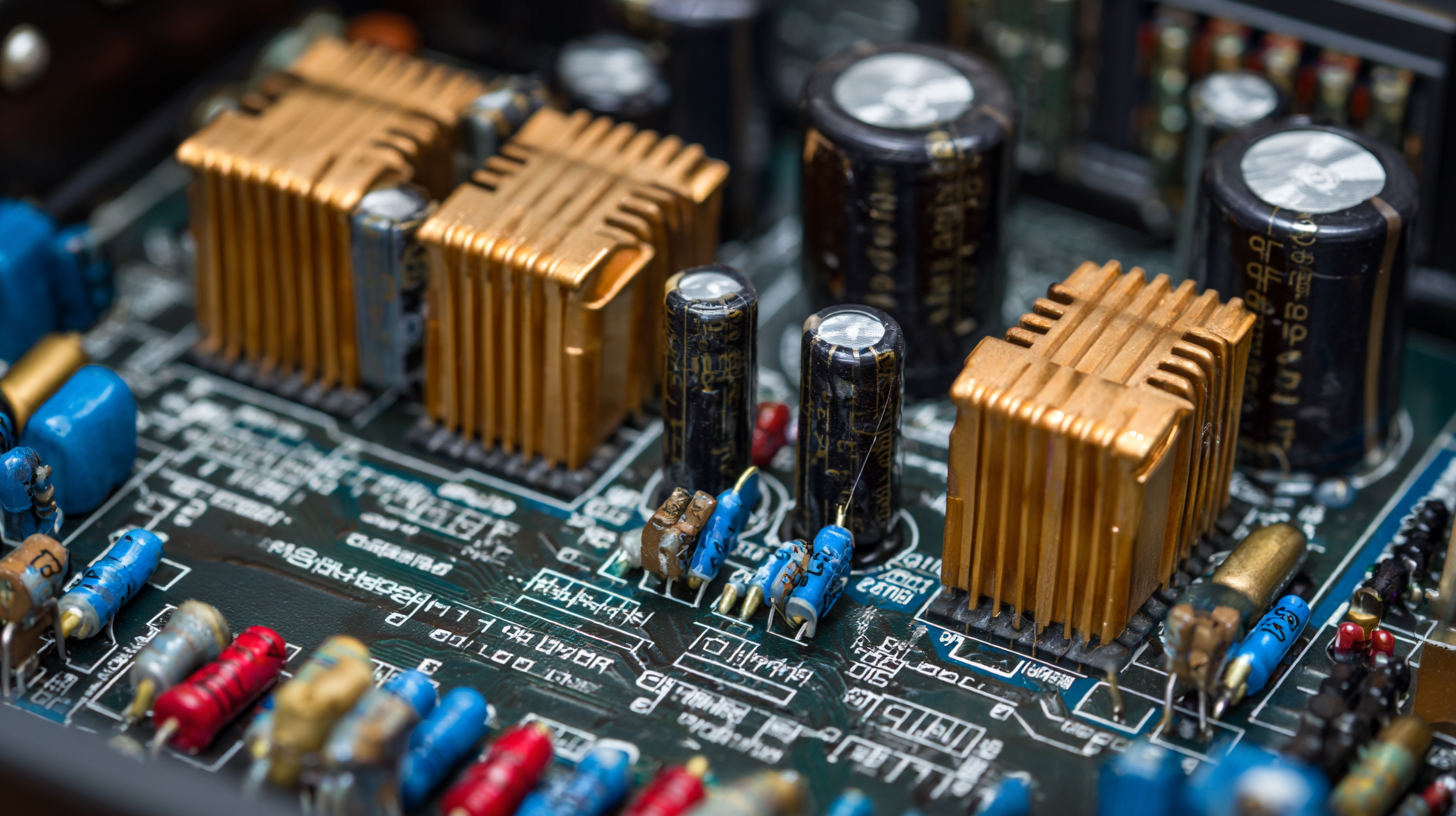

This chart illustrates the efficiency and performance differences between 50Hz and 60Hz frequency converters. The data includes converter efficiency rates and average power output across various applications.

Understanding the Technical Specifications of 50Hz to 60Hz Frequency Converters

When considering the technical specifications of 50Hz to 60Hz frequency converters, one of the most critical aspects is their efficiency rating. According to a report by the International Electrotechnical Commission (IEC), high-efficiency converters can reach up to 98% efficiency, minimizing energy losses and making them a cost-effective solution for industrial applications. This is particularly important in regions where energy costs fluctuate significantly, making every watt saved a substantial financial advantage.

Another significant factor is the converter’s harmonic distortion levels. A study by the IEEE indicates that frequency converters with low total harmonic distortion (THD) levels below 5% can dramatically reduce equipment wear and operational issues within electrical systems. This is essential for applications that rely on precision machinery, where even slight disturbances can lead to significant downtimes and losses.

Additionally, the environmental considerations of such converters cannot be overlooked. As reported in the Global Energy Assessment, adopting modern frequency converters can lead to a reduction in carbon footprints by optimizing energy conversion processes and lowering overall energy consumption. This aspect not only aligns with industry standards but also supports global sustainability goals, making 50Hz to 60Hz frequency converters a vital component in modern electrical engineering.

The Role of Frequency Converters in Electrical Equipment Efficiency

Frequency converters play a crucial role in enhancing the efficiency of electrical equipment by facilitating the transition between different power supply frequencies, notably from

50Hz to

60Hz. This is particularly important in a

globalized economy, where equipment and machinery often need to operate reliably in regions with differing electrical standards. By using a frequency converter, businesses can ensure that their devices maintain

optimal performance levels regardless of the local frequency, thus reducing downtime and operational issues.

Moreover, frequency converters can significantly impact energy consumption and overall performance. By allowing machines to run at their ideal frequency, these devices help to minimize energy waste and lower operational costs. Additionally, they contribute to better load management and improved power factor, which can enhance the lifespan of electrical equipment. As industries increasingly integrate

advanced technologies, the importance of efficient frequency conversion is more pronounced, ensuring that equipment operates efficiently while adapting to the specific demands of various applications.

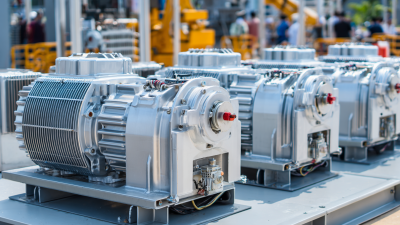

Common Applications of 50Hz to 60Hz Frequency Converters in Industry

In many industrial applications, frequency converters that transition power supply from 50Hz to 60Hz are becoming increasingly vital. These devices support a variety of uses, particularly in maritime environments where shore power systems play a crucial role. The shift towards maritime shore power solutions, as mandated by environmental regulations, exemplifies the growing importance of frequency converters in reducing emissions while providing reliable power to vessels at berth. Recent trends indicate that the shore power segment is on the rise, driven by stricter legislative frameworks and the need for modular, portable solutions that can cater to different types of vessels.

Frequency converters are not only pivotal in marine applications but also find extensive use in other sectors such as electric railways and industrial automation. For instance, specific configurations of frequency converters are employed in traction systems for railway vehicles, enhancing energy efficiency and operational reliability. The market for these converters is poised for significant growth, with forecasts predicting an annual growth rate of over 6% in the adoption of power electronics technologies that include frequency converters. This evolving landscape highlights the necessity for industries to embrace advanced frequency conversion solutions to optimize their operations and meet modern energy demands.

Important Safety Considerations When Using Frequency Converters in Electrical Systems

When using frequency converters in electrical systems, safety considerations are paramount. Frequency converters, which enable the conversion of 50hz to 60hz power supply, require careful handling to avoid potential hazards. It's crucial to ensure proper insulation and grounding to prevent electrical shocks and short circuits. Additionally, users must be aware of the thermal management of these devices, as overheating can lead to equipment failure or even fire. Regular maintenance checks are essential to ensure the optimal functioning of frequency converters, minimizing risks associated with wear and tear.

Moreover, with the growing demand for high-capacity frequency converters, particularly in industries like nuclear energy, special attention must be paid to the specifications and regulatory compliance of these devices. The rise of domestic innovations in China’s frequency converter market exemplifies this trend, highlighting the importance of rigorous testing and certification processes to ensure safety standards are met. Users should not only consider the efficiency and cost-effectiveness of frequency converters but also place a strong emphasis on their safety features to protect both workers and equipment.

Related Posts

-

How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs

-

How to Seamlessly Upgrade from Single Phase to Three Phase Power Systems

-

How to Choose the Right Power Converter for Your Specific Needs

-

Understanding the Mechanisms Behind Single Phase to Three Phase Converters in Modern Energy Systems

-

Mastering the Basics: A Step-by-Step Guide to Using 3 Phase Frequency Converters

-

The Future of Solid State Frequency Converters Redefining Power Management