Understanding the Functionality and Benefits of Rotary Phase Converters

In the world of industrial machinery, efficient power management is critical, and the use of a rotary phase converter is becoming increasingly prevalent. According to a report by the National Electrical Manufacturers Association, approximately 30% of all industrial motors in the U.S. are three-phase, highlighting the need for effective solutions to power single-phase lines.

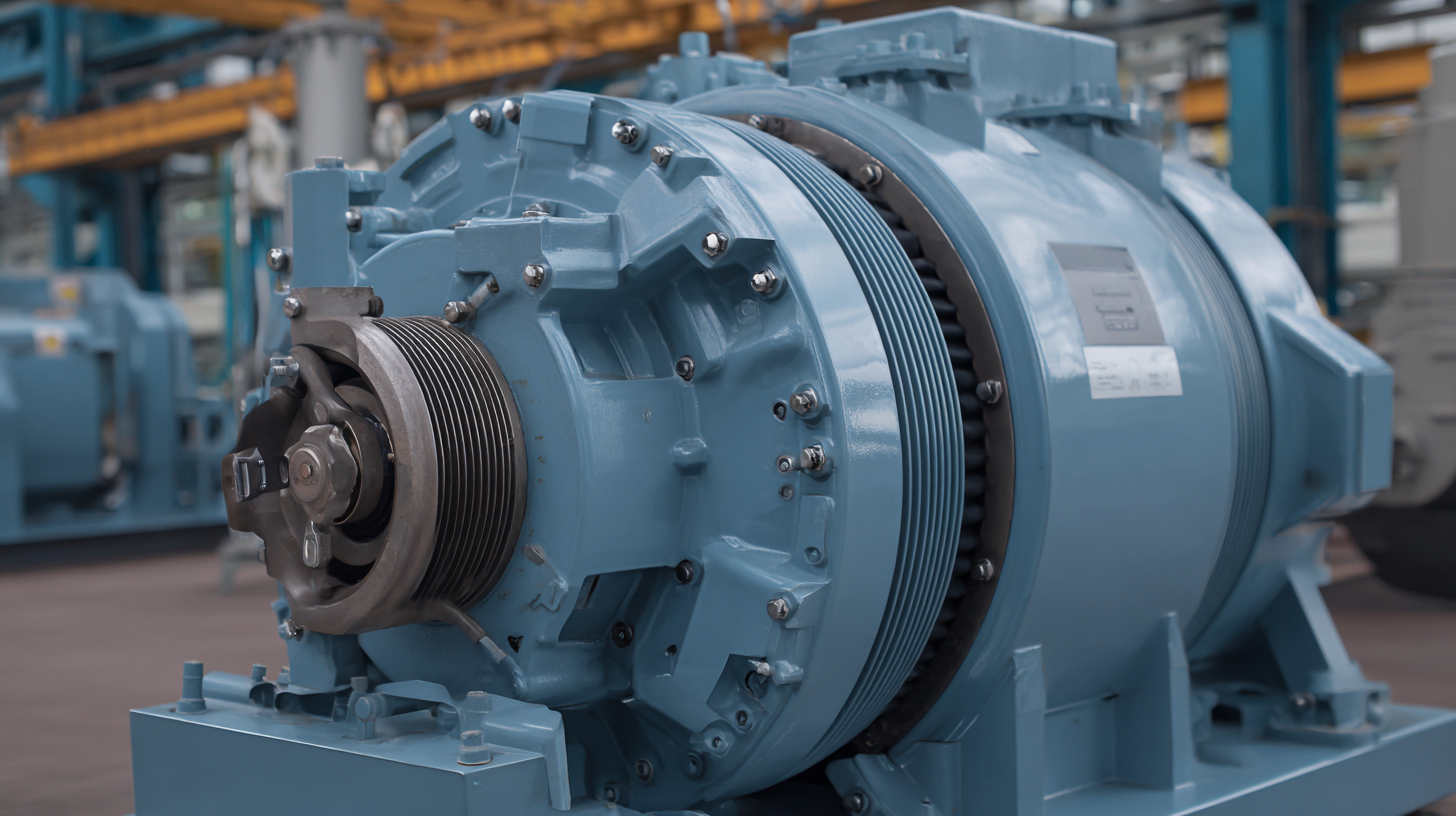

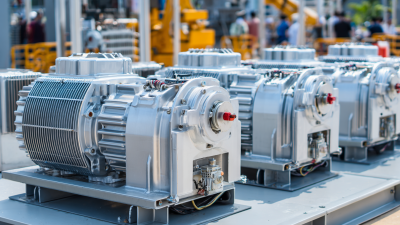

Rotary phase converters serve as invaluable tools by converting single-phase electricity into three-phase power, enabling businesses to operate larger machines without the significant investment of upgrading the existing electrical infrastructure. This not only enhances productivity but also leads to cost savings and improved energy efficiency.

As industries strive to streamline operations and reduce downtime, understanding the functionality and benefits of rotary phase converters becomes paramount. In this blog, we will delve into their operational principles, advantages, and tips for effective implementation.

Benefits of Using Rotary Phase Converters in Industrial Applications

Rotary phase converters are essential devices for converting single-phase electrical power into three-phase power, making them invaluable in various industrial applications. One of the primary benefits of using rotary phase converters is their ability to efficiently run three-phase motors without the need for expensive utility upgrades. This cost-effectiveness allows small to medium-sized enterprises to operate machines that require three-phase power without incurring high installation costs, thus facilitating production and enhancing profitability.

Another significant advantage of rotary phase converters is their versatility and reliability. They can operate multiple three-phase loads simultaneously, providing a seamless power supply for various equipment, from lathes to pumps. Additionally, these converters help maintain consistent voltage levels, reducing the risk of equipment damage and ensuring that operations run smoothly. By bridging the gap between single-phase supply and three-phase demands, rotary phase converters empower businesses to harness the full potential of their machinery, leading to increased efficiency and productivity across industrial sectors.

Understanding the Functionality and Benefits of Rotary Phase Converters - Benefits of Using Rotary Phase Converters in Industrial Applications

| Feature | Description | Benefits |

|---|---|---|

| Phase Conversion | Converts single-phase power to three-phase power. | Enables the use of three-phase equipment in locations with only single-phase supply. |

| High Starting Torque | Provides higher starting torque for motors. | Suitable for heavy loads and applications requiring aggressive startup. |

| Cost-Effective | Lower initial investment compared to installing three-phase wiring. | Reduces capital expenditure for small to mid-sized operations. |

| Durability | Constructed from robust materials for long-term use. | Lower maintenance costs and increased equipment lifespan. |

| Versatility | Can be used in various industrial applications. | Enhances operational flexibility across different machinery. |

| Energy Efficiency | Optimizes energy usage of motor-driven equipment. | Reduces overall energy costs in industrial applications. |

Key Differences Between Rotary and Static Phase Converters

When exploring the functionality of rotary and static phase converters, understanding their key differences is essential for optimizing industrial operations. Rotary phase converters, which utilize rotating machinery to convert single-phase power into three-phase power, offer a more robust solution than static phase converters. Static converters are simpler and cheaper, but they are limited in performance, particularly under heavy loads, which can generate imbalance issues leading to motor overheating and reduced lifespan. In contrast, rotary converters provide consistent voltage and current balance, making them ideal for driving critical equipment like induction motors and CNC machines.

**Tip:** When selecting a phase converter, consider the specific power requirements of your equipment. For applications needing reliable power with low harmonics, rotary converters are typically the better choice. Industry reports indicate that systems with balanced voltage features tend to increase equipment life by 25%, underscoring the long-term benefits of investing in more sophisticated solutions.

Moreover, advancements in power electronics, such as the design of time-based fault tolerance techniques in photovoltaic systems, highlight the importance of reliability in electrical systems. This reliability can also extend to phase converters, where innovative strategies are being researched to enhance performance under varying conditions, like temperature fluctuations and load changes. Ensuring the right phase converter is in place can significantly improve operational efficiency and reduce downtime, vital for maintaining productivity in an increasingly competitive environment.

Optimal Sizing and Selection of Rotary Phase Converters: A Complete Guide

When it comes to selecting a rotary phase converter, optimal sizing is crucial for ensuring efficient operation and meeting your power requirements. The first step in this process is to assess the total horsepower needed for your three-phase motors. This involves evaluating the startup and running needs of all connected equipment, as overload conditions can strain the converter and diminish its lifespan. Typically, rotary phase converters are rated based on their capacity to handle multiple motors, and it's important to factor in the maximum load each motor will draw.

Once you have established your power requirements, the next step is to choose the right type of rotary phase converter. There are several models available, including static converters and manual rotary converters, each suited to different applications. A manual rotary phase converter is often favored for its versatility in handling varying loads, while static converters work well for lower horsepower applications. Additionally, consider the physical space available for installation, as the size and design of the converter can affect your overall setup. By carefully sizing and selecting the appropriate rotary phase converter, you can enhance both efficiency and reliability in a variety of industrial and commercial settings.

Cost Efficiency: Analyzing Savings with Rotary Phase Converters

Rotary phase converters are increasingly recognized for their cost efficiency, especially for businesses seeking to operate three-phase equipment on a single-phase power supply. By converting single-phase electricity into three-phase power, these devices not only enable access to more extensive machinery but also significantly lower operational costs. Instead of upgrading to a more expensive utility service or investing in new three-phase equipment, companies can effectively utilize their existing single-phase connections, yielding substantial savings.

Moreover, the long-term benefits of rotary phase converters extend beyond mere installation savings. They lead to reduced energy consumption and lower wear and tear on machinery, which translates to lower maintenance costs over time. Businesses frequently report that their operational efficiency improves with rotary phase converters, as machines run smoother and require fewer repairs. As a result, the initial investment is quickly offset by the prolonged lifespan of equipment and the overall decrease in operational expenses, making rotary phase converters an economically sound choice for various industries.

Cost Efficiency: Analyzing Savings with Rotary Phase Converters

Common Misconceptions About Rotary Phase Converters in Today's Market

Rotary phase converters are often surrounded by misconceptions that can cloud their benefits and functionality in today’s industrial landscape. Many perceive rotary phase converters as outdated technology, primarily due to the surge in variable frequency drives (VFDs). However, industry reports, such as those from the National Electrical Manufacturers Association, indicate that rotary phase converters are still highly effective for powering three-phase motors, especially in applications where high starting torque is essential. Their robustness and simplicity make them suitable for small to mid-sized manufacturing operations that may not have access to three-phase line power.

One common myth is that rotary phase converters are inefficient compared to modern alternatives. In reality, studies show that well-designed rotary phase converters can achieve efficiency levels of up to 95%, providing a cost-effective solution for business owners. This efficiency becomes even more pronounced in environments where multiple motors are in operation, as rotary phase converters can distribute power effectively while minimizing energy waste.

Tips: When selecting a rotary phase converter, consider the total horsepower needed and ensure the converter is rated to handle that load. It's also beneficial to consult with a knowledgeable supplier who can provide insights into optimizing system design to increase performance and reduce operational costs. Regular maintenance checks can further enhance the lifespan and reliability of your rotary phase converter setup.

Related Posts

-

Step-by-Step Guide: How to Effectively Use a Single to Three Phase Converter in Your Projects

-

How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs

-

How to Choose the Right Electronic Converter for Your Business Needs

-

The Future of Solid State Frequency Converters Redefining Power Management

-

Mastering the Basics: A Step-by-Step Guide to Using 3 Phase Frequency Converters

-

5 Reasons to Upgrade to a 400hz Power Supply for Enhanced Performance and Efficiency