Understanding Phase Converter 1 to 3 Benefits and Applications for Your Needs

In the ever-evolving landscape of industrial technology, understanding the intricacies of "phase converter 1 to 3" systems has become increasingly essential for manufacturers and businesses alike. According to industry expert Dr. Michael Carson, a recognized authority on electrical engineering and power systems, “The utilization of phase converters not only amplifies operational efficiency but also expands the versatility of equipment.” This perspective underscores the importance of these converters in bridging the gap between single-phase and three-phase power sources, ultimately enhancing productivity across various applications.

Phase converters serve as a pivotal tool in transforming single-phase electricity into three-phase power, enabling businesses to harness the capabilities of robust machinery and equipment that require three-phase input. The effective application of a phase converter 1 to 3 can lead to significant benefits, including increased power availability, improved equipment performance, and the capacity to operate a wider range of tools without the need for substantial electrical infrastructure upgrades.

As industries continue to seek innovative solutions for operational challenges, understanding the benefits and applications of phase converter 1 to 3 systems will play a critical role in ensuring that businesses remain competitive and can fully leverage their resources for maximum output. Exploring the advantages offered by these converters can provide valuable insights for organizations looking to optimize their operations.

Understanding Phase Converter: Definition and Functionality

A phase converter is an electrical device that enables the conversion of single-phase power into three-phase power. This is particularly essential in areas where three-phase power is not readily available, allowing industrial and commercial equipment requiring three-phase electricity to operate effectively. Essentially, phase converters help bridge the gap between different power systems, ensuring that businesses can run their machinery without interruption, thus facilitating higher efficiency and productivity.

The functionality of a phase converter involves several mechanisms, depending on the type of converter utilized—rotary or static. Rotary phase converters utilize a rotating generator that creates the necessary phase and voltage balance, while static phase converters rely on capacitors to momentarily assist the electrical load. Both types can support a wide range of applications, from powering heavy machinery in manufacturing plants to enabling larger HVAC systems and commercial refrigeration units.

By transforming power formats, phase converters play a crucial role in maintaining operational continuity and energy efficiency in an increasingly electrified world.

Key Benefits of Using Phase Converters in Various Applications

Phase converters play a crucial role in various applications, enabling users to harness the benefits of three-phase power from a single-phase supply. One of the key advantages of these devices is the ability to power three-phase motors, which are commonly used in industrial and commercial settings. By converting single-phase electricity into three-phase power, phase converters allow businesses to operate heavy machinery and equipment that require more robust energy sources, enhancing productivity and efficiency.

Another significant benefit of using phase converters is their cost-effectiveness. Instead of upgrading to a three-phase electrical service, which can be expensive and time-consuming, phase converters provide an economical solution for small to medium-sized businesses. This flexibility ensures that companies can maintain their operations without incurring high installation costs while still benefiting from the performance and reliability associated with three-phase systems. Additionally, phase converters are relatively easy to install and maintain, making them an attractive option for various manufacturing and commercial applications.

Common Applications of Phase Converters in Industry and Home Use

Phase converters are essential devices that allow single-phase electrical power systems to operate three-phase machinery. Their applications are widespread across various industries and home settings, providing flexibility and efficiency in operations. In industrial environments, phase converters enable the use of three-phase equipment, which is often more powerful and efficient than single-phase alternatives. They facilitate the operation of motors, pumps, and other heavy machinery that are crucial to manufacturing processes without the need for extensive rewiring or new electrical service installation.

In residential applications, phase converters are particularly beneficial for homeowners who wish to utilize three-phase equipment for DIY projects or to power home workshops. These devices enable access to powerful tools, such as lathes, mills, and compressors, which require three-phase power but may not be readily available in residential areas. By employing a phase converter, users can significantly enhance their capabilities while ensuring that their tools operate at peak performance. This versatility makes phase converters an invaluable asset both in commercial settings and home use, fostering greater productivity across various tasks.

Choosing the Right Phase Converter for Your Specific Needs

When selecting the right phase converter for your specific needs, understanding the different types and their applications is crucial. Phase converters, particularly rotary and static types, are widely used to convert single-phase power into three-phase power, essential for running three-phase equipment efficiently. According to a report by the National Electrical Manufacturers Association (NEMA), the demand for three-phase motors in industrial settings has surged by approximately 15% annually over the past five years, indicating a growing reliance on systems that require more robust power sources.

In choosing a phase converter, factors such as the total horsepower required, voltage specifications, and the type of load being used play significant roles. A survey conducted by the American National Standards Institute (ANSI) found that nearly 60% of businesses using phase converters opt for rotary converters due to their superior efficiency and capability of handling varying loads without significant performance drops. This efficiency not only enhances productivity but also reduces electricity costs over time, making it a preferred choice for facilities with high operational demands.

Additionally, understanding the distinct applications of each type of converter can streamline your decision-making process. For instance, while static converters are ideal for light-duty applications such as small machinery, rotary converters are better suited for heavy-duty industrial equipment, as they provide smoother power flow and better startup capabilities. This comprehensive understanding ensures that you choose a phase converter that not only meets your immediate operational needs but also provides long-term benefits in productivity and efficiency.

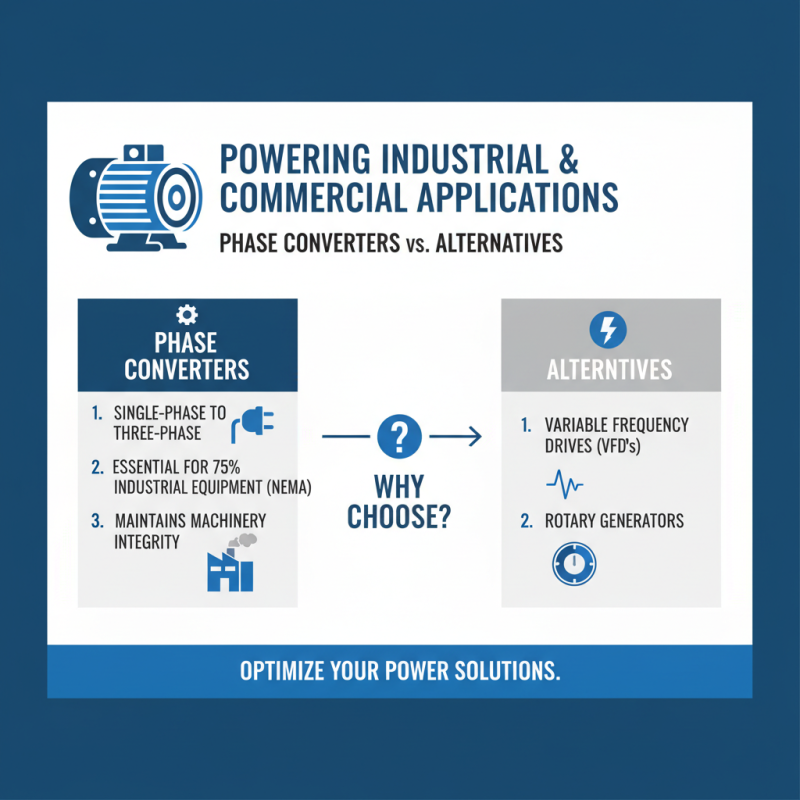

Comparative Analysis: Phase Converter vs Other Power Solutions

When evaluating power solutions for industrial and commercial applications, the choice between phase converters and alternative options such as variable frequency drives (VFDs) or rotary generators is critical. Phase converters, particularly those converting single-phase to three-phase power, offer unique advantages that are worth considering. According to a report by the National Electrical Manufacturers Association (NEMA), around 75% of industrial equipment is designed to operate on three-phase power, making phase converters an essential consideration for businesses looking to upgrade their machinery or energy systems. The ability of phase converters to provide the necessary power while maintaining the integrity of the machinery is a significant factor for many operators.

In contrast to VFDs, which regulate motor speed and torque, phase converters excel in delivering consistent power for multiple machines running simultaneously. A study by the Electric Power Research Institute (EPRI) found that businesses utilizing phase converters reported less downtime due to power fluctuations, which can compromise production efficiency and equipment lifespan. Furthermore, unlike rotary generators that often require extensive maintenance and higher upfront costs, phase converters provide a more cost-effective and low-maintenance alternative, generating substantial ROI over time as operational efficiency increases. This comparative analysis highlights the practicality of phase converters in supporting diverse manufacturing processes while ensuring reliable and stable power output.

Related Posts

-

Ultimate Guide to Understanding Phase Converters for 1 to 3 Power Conversion

-

Understanding the Benefits of Phase Converters: Transforming 1-Phase to 3-Phase Power Efficiently

-

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency

-

How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs

-

Exploring the Impact of Rotary Phase Converters on Industrial Growth at the 2025 China 138th Import and Export Fair

-

2025 Top 5 Three Phase to Single Phase Converters for Efficient Power Conversion