Top 5 Three Phase Converters: Enhance Efficiency and Power Quality

In today’s rapidly evolving industrial landscape, the demand for efficient and reliable power systems has never been greater. As companies strive to enhance their operational efficiency and maintain high power quality, the role of three phase converters becomes increasingly critical. These devices are pivotal in converting single-phase power into three-phase power, allowing for smoother operation of various types of machinery and equipment. This not only improves performance but also significantly reduces energy losses.

In this article, we will explore the top five three phase converters available on the market. Each option will be examined for its efficiency, reliability, and impact on power quality, providing insights for businesses looking to invest in the right technology. By understanding the advantages and features of these converters, industries can make informed decisions that bolster their productivity and sustainability efforts. Join us as we delve into the world of three phase converters and highlight the essential models that can enhance both operational efficiency and the overall quality of power in industrial settings.

Understanding the Basics of Three Phase Converters for Enhanced Performance

Three phase converters play a crucial role in enhancing the efficiency and power quality of various industrial applications. By converting single-phase power to three-phase power, these converters can significantly improve the performance of motors and other electrical equipment. According to a recent report from the International Electrotechnical Commission (IEC), utilizing three phase systems can boost operational efficiency by up to 30%, ultimately reducing energy costs for businesses. This efficiency is attributed to the ability of three-phase systems to deliver a consistent and balanced power flow, which minimizes the risk of electrical imbalances that can lead to equipment wear and tear.

Understanding the fundamentals of three phase converters is essential for optimizing their use. These converters can be categorized into different types, such as matrix converters and PWM (Pulse Width Modulation) converters, each offering unique advantages. For instance, a study conducted by the Electric Power Research Institute (EPRI) highlighted that PWM converters are known for their superior performance in environments with variable loads, improving total harmonic distortion (THD) by over 20% compared to traditional converters. By diving into the specific characteristics and applications of three phase converters, industries can select the right technology that not only enhances performance but also ensures long-term reliability and cost savings.

Top 5 Three Phase Converters: Enhance Efficiency and Power Quality

| Converter Type | Max Power Rating (kW) | Input Voltage (V) | Output Voltage (V) | Efficiency (%) | Total Harmonic Distortion (%) |

|---|---|---|---|---|---|

| Delta Converter | 75 | 400 | 400 | 97 | 5 |

| Wye Converter | 100 | 480 | 480 | 95 | 3 |

| VFD Converter | 150 | 600 | 400 | 98 | 4 |

| Phase Shift Converter | 200 | 480 | 480 | 96 | 3.5 |

| Active Front End Converter | 300 | 400 | 400 | 99 | 1 |

Types of Three Phase Converters: A Comprehensive Overview

Three-phase converters are essential devices in modern electrical systems, significantly improving energy efficiency and power quality. These converters are classified into several types, each serving unique use cases and functionalities. The main types include diode rectifiers, thyristor-based converters, and inverter converters. Diode rectifiers are commonly used in industrial applications for their simplicity and reliability, allowing for efficient conversion of AC to DC power. Thyristor-based converters offer controlled power delivery and are ideal for applications requiring variable speed control, such as in electric drives.

Another notable type is the inverter converter, which reverses the process by converting DC back into AC, thus allowing for greater versatility in energy systems. In addition to these basic types, there are also more advanced configurations, like active front-end converters, which provide improved power factor regulation and reduced harmonics for enhanced system performance. Understanding these different types of three-phase converters is crucial for selecting the right solution to meet specific operational needs, fostering both efficiency and superior power quality in electrical applications.

Top 5 Three Phase Converters: Efficiency and Power Quality

This chart illustrates the efficiency and power quality of the top five types of three phase converters, highlighting their operational characteristics.

Key Factors to Consider When Choosing a Three Phase Converter

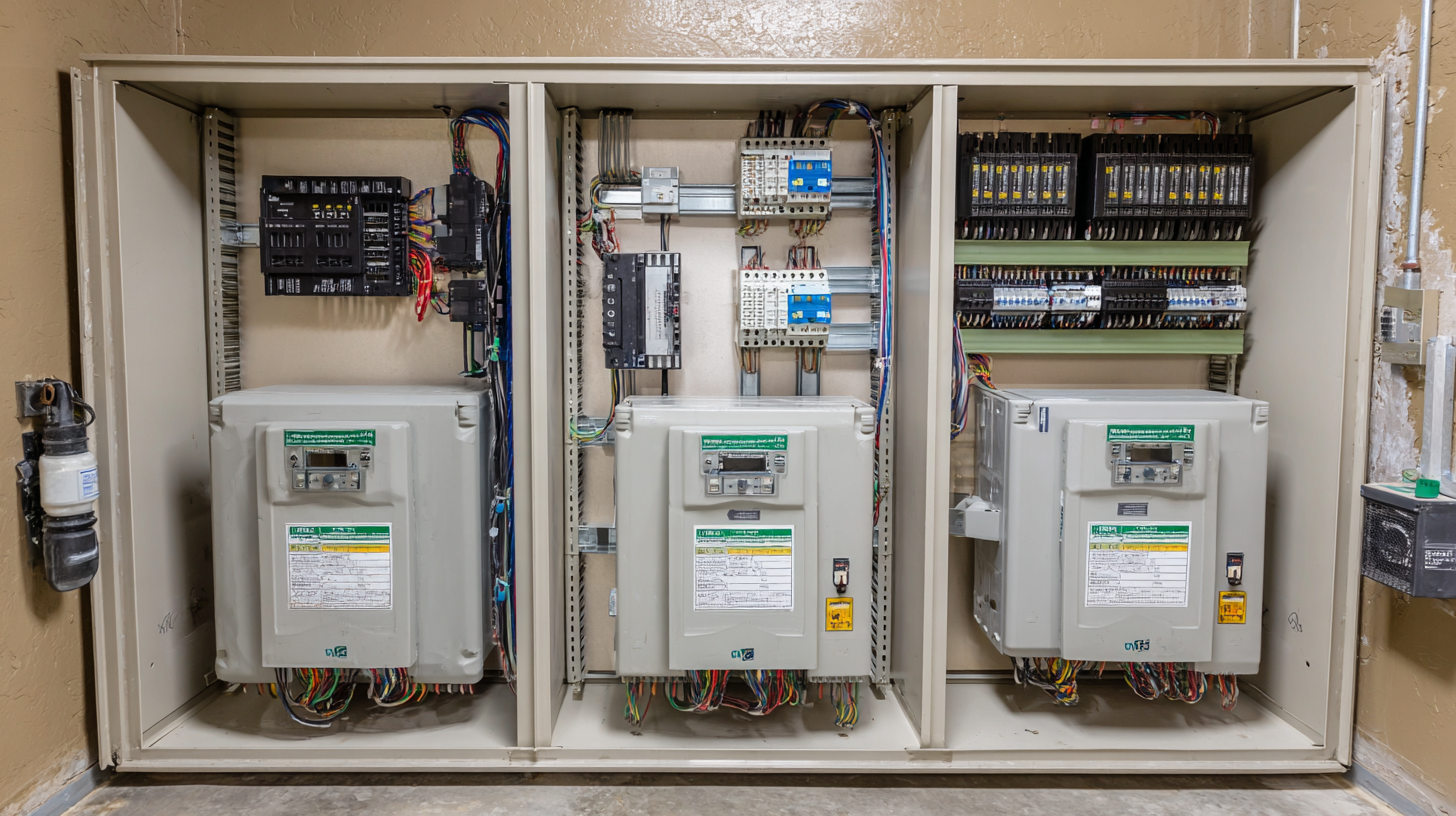

When choosing a three-phase converter, several key factors must be taken into account to ensure optimal efficiency and power quality. First, the converter's power rating should match the requirements of the connected load. This helps prevent underperformance or overload situations. It is also essential to consider the converter's efficiency ratings, as higher efficiency translates to lower energy losses and reduced operating costs.

Another critical factor is the type of converter—whether it’s an inverter, rectifier, or a static converter. Each type offers different benefits depending on the application, so understanding their functionalities is vital. Additionally, features such as harmonic distortion levels, voltage regulation, and thermal performance are crucial for improving overall system stability. A reliable manufacturer with good customer support and warranty options is also important for ensuring long-term performance and maintenance of the converter. Making an informed choice based on these factors can greatly enhance both the efficiency and power quality of industrial and commercial applications.

Maximizing Efficiency with Advanced Three Phase Converter Features

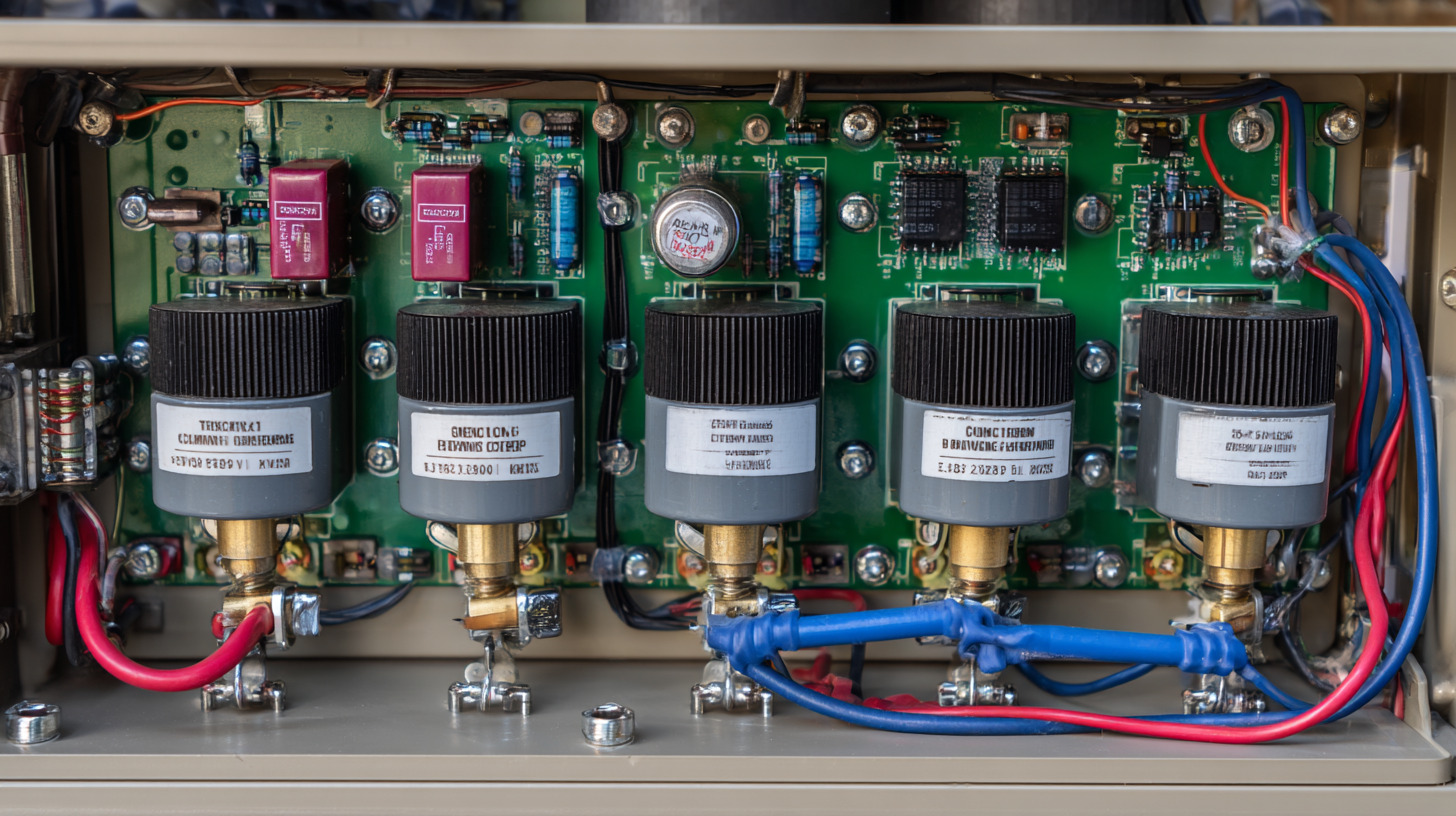

Three-phase converters play a crucial role in enhancing the efficiency and power quality in industrial applications. By converting single-phase power to three-phase, these converters allow for better distribution of energy among motors and other heavy machinery.

Advanced features such as digital signal processing, voltage regulation, and real-time monitoring contribute significantly to optimizing performance. These technologies not only improve efficiency but also help maintain stable power output, thus reducing the risk of equipment failure and downtime.

Three-phase converters play a crucial role in enhancing the efficiency and power quality in industrial applications. By converting single-phase power to three-phase, these converters allow for better distribution of energy among motors and other heavy machinery.

Advanced features such as digital signal processing, voltage regulation, and real-time monitoring contribute significantly to optimizing performance. These technologies not only improve efficiency but also help maintain stable power output, thus reducing the risk of equipment failure and downtime.

Moreover, modern three-phase converters are designed to minimize harmonic distortion, which can adversely affect power quality. By implementing active front-end technology and employing passive filters, these converters can effectively mitigate the impact of harmonics. This results in smoother operation, improved lifespan of connected equipment, and lower energy costs. With features like intelligent control algorithms, users can maximize their energy savings while ensuring that their systems operate at peak performance. Emphasizing these advanced features allows businesses to achieve long-term operational excellence and sustainability in their energy consumption.

Improving Power Quality: Best Practices for Installation and Maintenance

When it comes to enhancing power quality in three-phase systems, proper installation and maintenance practices are essential. According to the Electric Power Research Institute (EPRI), poor installation practices can lead to significant voltage imbalances, resulting in up to 10% reduction in efficiency and increased operational costs for industrial facilities. Therefore, ensuring that converters are installed by qualified professionals and that they adhere to manufacturer specifications is paramount.

Regular maintenance is equally critical for sustaining optimal performance. A study by the International Energy Agency (IEA) highlighted that facilities that implemented systematic maintenance schedules for their converters experienced a 20% decrease in unexpected downtimes. Key maintenance practices include regular inspections of cooling systems, checking for loose connections, and ensuring that the harmonics generated by the converters are within acceptable limits. By proactively addressing potential issues, companies not only enhance operational reliability but also contribute to improved overall power quality.

Related Posts

-

2025 Top 5 Three Phase to Single Phase Converters for Efficient Power Conversion

-

Mastering the Basics: A Step-by-Step Guide to Using 3 Phase Frequency Converters

-

Unlocking the Benefits of 3 Phase Power Converters: A Comprehensive Guide for Efficient Energy Use

-

Maximizing Efficiency with the Best Single to Three Phase Converters for Your Business Needs

-

Exploring the Impact of Rotary Phase Converters on Industrial Growth at the 2025 China 138th Import and Export Fair

-

Comprehensive Guide to Choosing the Right Voltage Frequency Converter for Optimal Performance