Top 10 60hz to 50hz Frequency Converters for Optimal Performance

In today's global economy, the efficiency and adaptability of electrical equipment are crucial, especially when dealing with varying power supply frequencies. Experts in the field, such as Dr. James Collins, a leading authority on electrical engineering and power systems, emphasize the importance of understanding frequency conversion. He states, "The ability to adapt equipment from 60Hz to 50Hz is vital for optimizing performance in a global market where electrical standards vary widely."

As technology advances, the demand for 60Hz to 50Hz frequency converters continues to grow. These converters not only ensure that machinery operates smoothly across different regions but also maximize operational efficiency and longevity of the equipment. For businesses looking to expand their reach, investing in a reliable 60Hz to 50Hz frequency converter can be a game changer.

In this article, we will explore the top ten frequency converters available in the market today, focusing on their features, benefits, and what sets them apart for achieving optimal performance. By understanding the options available, businesses can make informed decisions that will enhance their operational capabilities in an increasingly interconnected world.

Understanding Frequency Conversion: 60Hz to 50Hz Explained

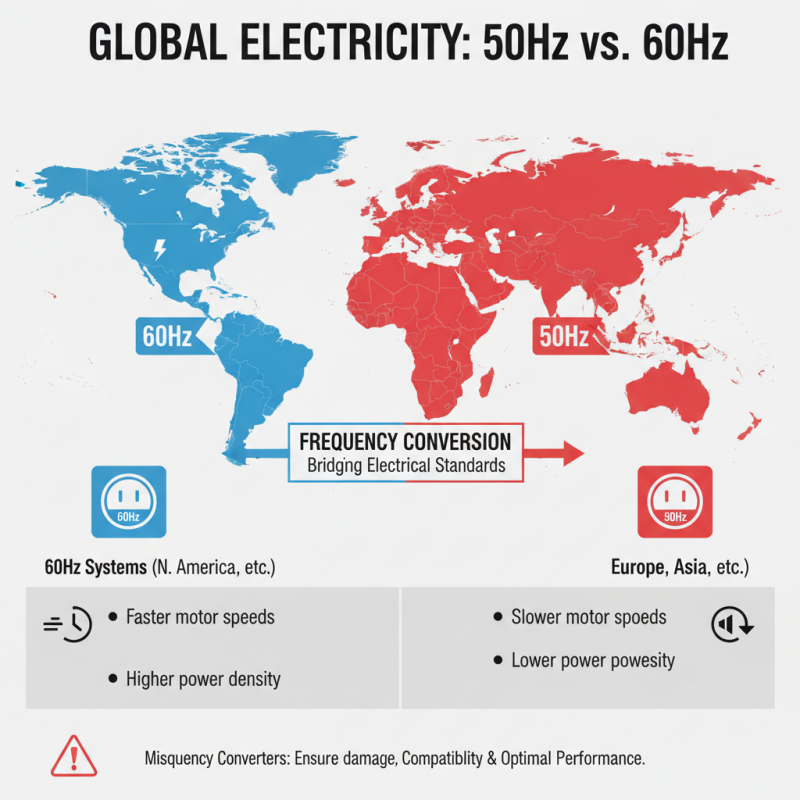

Frequency conversion is essential for regions that operate on different electrical standards, particularly between 60Hz and 50Hz systems. The primary distinction lies in the frequency of the alternating current supplied, which can significantly affect the performance of electrical devices. Many countries, including the United States and Canada, utilize 60Hz, while most of Europe and parts of Asia rely on 50Hz. This discrepancy can lead to issues with devices designed for one frequency when used in an environment operating on another.

A 60Hz to 50Hz frequency converter works by altering the electrical frequency to match the required standards of the connected equipment. This conversion is crucial for the optimal performance and longevity of motors, appliances, and industrial machinery, as running these devices on the incorrect frequency can result in overheating, inefficiency, or outright failure. When implementing such systems, users should consider factors like load type, power quality, and the specific requirements of their devices to ensure a smooth transition and reliable operation. Understanding these nuances is vital for effectively utilizing frequency converters and maintaining the integrity of electrical systems.

Key Features to Consider in Frequency Converters

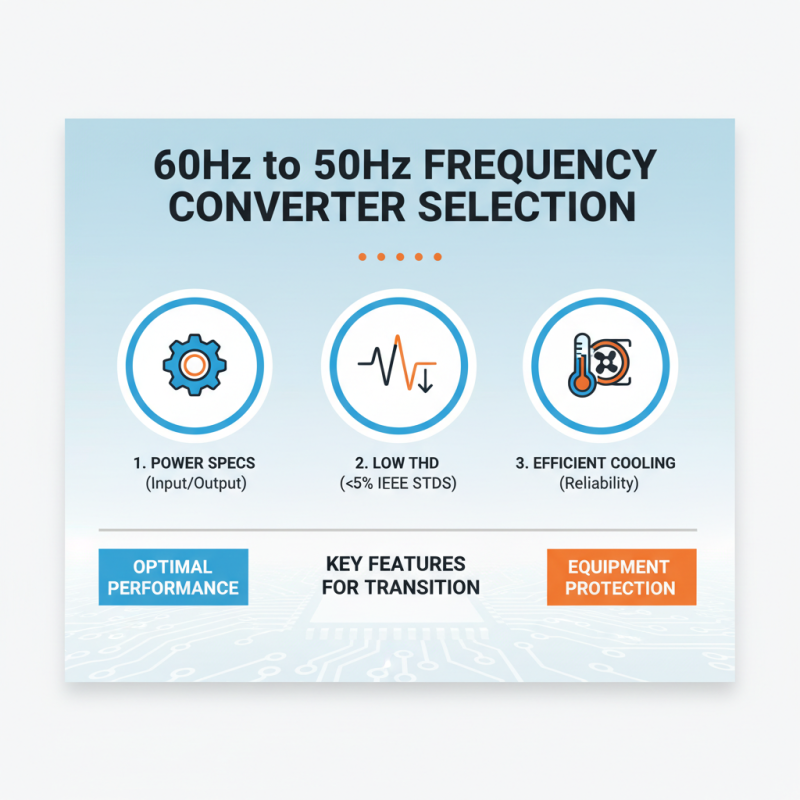

When selecting a frequency converter, especially those transitioning from 60Hz to 50Hz, several key features must be carefully considered to ensure optimal performance. First, pay close attention to the converter's input and output power specifications. A reliable frequency converter should handle the required load without overheating or causing inefficiencies. According to the IEEE standards on power quality, these converters should maintain a total harmonic distortion (THD) of less than 5% to comply with performance benchmarks, ensuring minimal impact on connected equipment.

Another crucial aspect to consider is the converter's efficiency rating. A high-efficiency rating—often over 95%—not only reduces operational costs but also lowers the overall carbon footprint, aligning with global sustainability efforts. Furthermore, features such as overload protection and built-in cooling systems are essential for prolonging the lifespan of the equipment. Industry research has shown that converters equipped with these protective measures can sustain optimum performance, significantly reducing maintenance costs over time.

**Tip:** When assessing frequency converters, always check for compliance with relevant international standards to ensure compatibility with your operational environment.

Additionally, look for models that offer advanced features like digital display interfaces or programmable settings. These can enhance usability and facilitate easier monitoring. Investing in a converter that balances performance, efficiency, and user-friendly features will ultimately lead to better operational stability and energy savings.

Top Brands Offering 60Hz to 50Hz Frequency Converters

When it comes to selecting a reliable frequency converter for converting 60Hz to 50Hz, various brands stand out due to their commitment to quality and performance. These top brands have developed specialized technologies that ensure smooth and efficient operation, catering specifically to industries that require synchronized power supply regardless of geographic power standards. Their converters are designed to minimize energy loss and enhance overall device longevity, making them essential for businesses that operate on both frequency standards.

Moreover, the emphasis on performance by these leading brands goes beyond simple conversion. They incorporate advanced features such as built-in protection mechanisms to guard against power surges and overloads, ensuring safety and reliability. In addition, many of these converters offer user-friendly interfaces, allowing operators to adjust settings easily for specific applications. This combination of innovation and practicality enables industries to seamlessly integrate equipment across different regions, maximizing efficiency and productivity while maintaining adherence to local power regulations.

Performance Comparison of Leading Frequency Converters

When evaluating frequency converters, the comparison of performance metrics is crucial for selecting the optimal device. For applications transitioning from 60Hz to 50Hz, efficiency, reliability, and output quality are key factors. Leading frequency converters vary in terms of their design, technology, and functionality, making it essential to assess their capabilities thoroughly. Users should focus on aspects such as voltage stability, harmonic distortion, and thermal management when comparing these devices.

Tips for selecting the right frequency converter include analyzing the specific power requirements of your application. Understand the load characteristics and ensure the converter can handle peak demands without compromising performance. It's also beneficial to look for models with advanced features like real-time monitoring and diagnostics to ensure seamless operation.

Additionally, consider the installation and maintenance aspects of the frequency converters. An easy-to-install unit can save time and reduce initial costs, while a design that allows for simple maintenance can enhance longevity and reliability. Frequent checks and updates on firmware may also contribute positively to the converter's performance, ensuring that it operates at optimal levels throughout its service life.

Performance Comparison of Leading Frequency Converters

This chart illustrates the efficiency percentage of the top 10 frequency converters operating at 60Hz to 50Hz. The data represents their respective performance, providing insights into which converters deliver optimal results for frequency conversion tasks.

Installation and Maintenance Tips for Frequency Converters

When it comes to the installation of frequency converters, proper planning and execution are essential for optimal performance. Begin by carefully reading the manufacturer’s installation manual to understand the electrical requirements and setup process tailored to your specific model. Ensure that the converter is mounted in a clean, dry environment with adequate ventilation to prevent overheating. It’s also crucial to verify the input and output connections, making sure they match the specifications of the equipment being powered. Additionally, employ appropriate tools when making connections to avoid damage and ensure a secure fit.

Maintenance of frequency converters is equally important to ensure longevity and efficient operation. Regular inspections should be carried out to check for accumulation of dust or debris, especially around ventilation grilles, which can impede airflow. Keep an eye on the performance metrics and watch for any unusual noises or vibrations, as these may indicate potential issues. Periodic software updates may also be necessary to enhance functionality and security. Lastly, always ensure that the converter is powered down before performing any maintenance work to ensure the safety of the technician and the integrity of the equipment.

Top 10 60hz to 50hz Frequency Converters for Optimal Performance - Installation and Maintenance Tips for Frequency Converters

| Model | Power Rating (kW) | Efficiency (%) | Weight (kg) | Dimensions (mm) | Warranty (Years) |

|---|---|---|---|---|---|

| Converter A | 10 | 95 | 25 | 300 x 200 x 150 | 2 |

| Converter B | 15 | 92 | 30 | 400 x 300 x 200 | 3 |

| Converter C | 20 | 94 | 40 | 500 x 350 x 250 | 4 |

| Converter D | 25 | 91 | 45 | 600 x 400 x 300 | 5 |

| Converter E | 30 | 89 | 50 | 700 x 450 x 350 | 6 |

| Converter F | 40 | 90 | 60 | 800 x 500 x 400 | 5 |

| Converter G | 50 | 93 | 70 | 900 x 550 x 450 | 6 |

| Converter H | 60 | 87 | 80 | 1000 x 600 x 500 | 7 |

| Converter I | 80 | 88 | 90 | 1100 x 650 x 550 | 8 |

| Converter J | 100 | 85 | 100 | 1200 x 700 x 600 | 5 |

Related Posts

-

How to Convert 60Hz to 50Hz: A Step-by-Step Guide for Your Electrical Devices

-

The Future of Solid State Frequency Converters Redefining Power Management

-

Unveiling New Innovations: 400Hz Frequency Converters at the 138th Canton Fair 2025

-

Understanding the Benefits of Phase Converters: Transforming 1-Phase to 3-Phase Power Efficiently

-

Step-by-Step Guide: How to Effectively Use a Single to Three Phase Converter in Your Projects

-

5 Reasons to Upgrade to a 400hz Power Supply for Enhanced Performance and Efficiency