Top 10 Frequency Inverter Benefits You Must Know in 2023

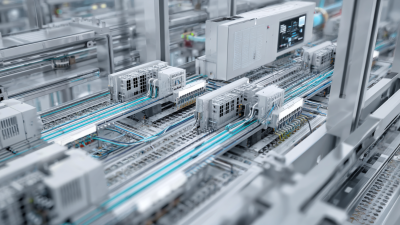

In the rapidly evolving landscape of industrial technology, the significance of frequency inverters has become increasingly prominent. As industry expert Dr. Emily Carter aptly states, “The implementation of frequency inverters not only enhances energy efficiency but also provides unparalleled control over motor operations.” This transformative device enables precise regulation of motor speed, leading to significant reductions in energy consumption and operational costs.

The benefits of frequency inverters extend beyond mere energy savings; they offer enhanced operational flexibility, improved equipment lifespan, and increased reliability. In 2023, as businesses strive to optimize their processes and adopt more sustainable practices, understanding the advantages of frequency inverters is crucial. These devices are revolutionizing how industries manage power, allowing for greater adaptability to fluctuating demands and contributing to a greener future.

As we delve into the top 10 benefits of frequency inverters, it becomes clear that they are no longer just auxiliary components; they have become essential tools in modern industrial applications. Knowing their capabilities can lead to improved performance and significant financial savings, making them indispensable in today’s competitive market.

Advantages of Using Frequency Inverters in Industrial Applications

Frequency inverters, also known as variable frequency drives (VFDs), play a crucial role in modern industrial applications by providing significant advantages that enhance operational efficiency. One of the primary benefits of using frequency inverters is their ability to adjust motor speed based on real-time demand. This dynamic control not only optimizes energy consumption but also reduces wear and tear on equipment, leading to longer operating life and lower maintenance costs.

Another key advantage of frequency inverters is their contribution to improved process control and precision. By allowing for smooth acceleration and deceleration, these devices prevent abrupt changes in speed that can cause mechanical stress. This enhanced control translates into better quality output in manufacturing processes, reducing defects and increasing overall productivity. Furthermore, frequency inverters can offer flexibility in managing multiple motors, enabling factories to streamline operations and adapt swiftly to varying production needs without compromising efficiency.

Energy Efficiency Improvements with Frequency Inverters

Frequency inverters, also known as variable frequency drives (VFDs), play a crucial role in improving energy efficiency across various applications in 2023. By regulating the speed and torque of electric motors, frequency inverters enable better control and optimization of energy consumption. This translates to significant reductions in operational costs, as motors only draw the necessary energy based on real-time needs rather than running at full capacity continuously.

One of the key tips for maximizing the energy savings potential of frequency inverters is to ensure they are properly sized for the application. Oversized inverters can lead to inefficiencies and wasted energy, undermining the benefits they provide. Additionally, integrating energy monitoring systems can help identify patterns in energy use, enabling further optimizations. Regular maintenance and periodic recalibration of the inverter settings can also contribute to sustained energy efficiency improvements.

Moreover, leveraging advanced features such as dynamic braking or regenerative operations with frequency inverters can enhance overall energy recovery in systems where energy can be feedback into the supply. This not only contributes to better energy utilization but can also improve system reliability and extend the lifespan of equipment, making frequency inverters an essential component in modern energy management strategies.

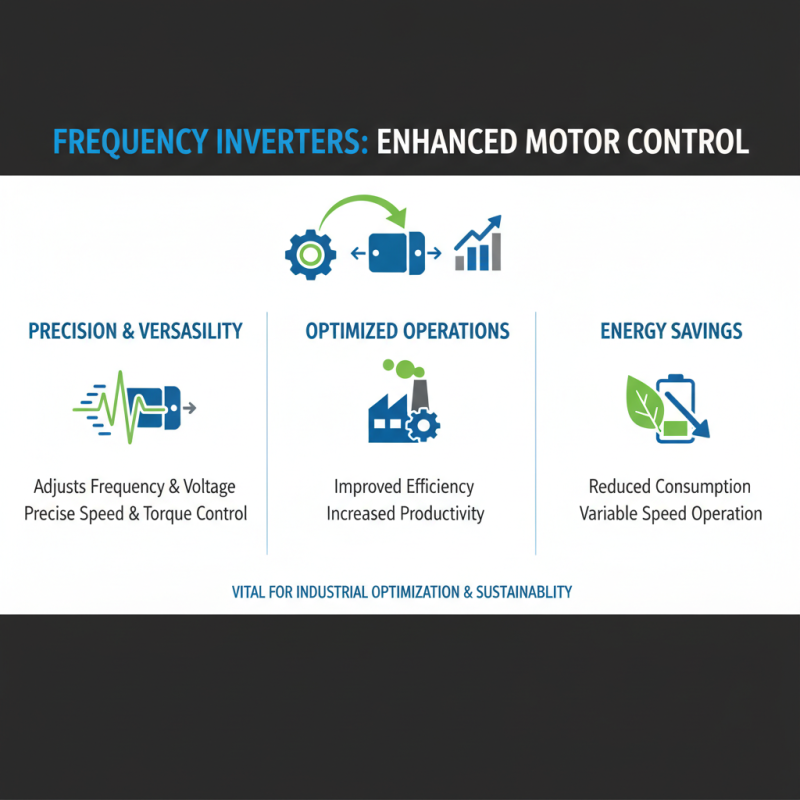

Enhanced Motor Control and Performance through Frequency Inverters

Frequency inverters play a crucial role in enhancing motor control and performance, making them a vital component in various industrial applications. By adjusting the frequency and voltage supplied to electric motors, these devices allow for precise control of motor speed and torque. This improved versatility enables businesses to optimize their operations, leading to increased efficiency and productivity. With the capability to operate at varying speeds, frequency inverters reduce energy consumption significantly, as motors can run at lower speeds when full power is unnecessary.

In addition to energy savings, frequency inverters also contribute to extended motor life. They enable smoother starts and stops, reducing mechanical stress on the motor and associated equipment. The soft-start feature lessens the impact of sudden load changes, which can lead to equipment wear and tear over time. Furthermore, frequency inverters provide enhanced diagnostic capabilities, enabling operators to monitor performance metrics in real-time. This proactive approach helps identify potential issues before they result in costly downtime, ensuring that operations remain seamless and reliable. Overall, the integration of frequency inverters marks a significant advancement in motor control technology, fostering improved performance and resource management.

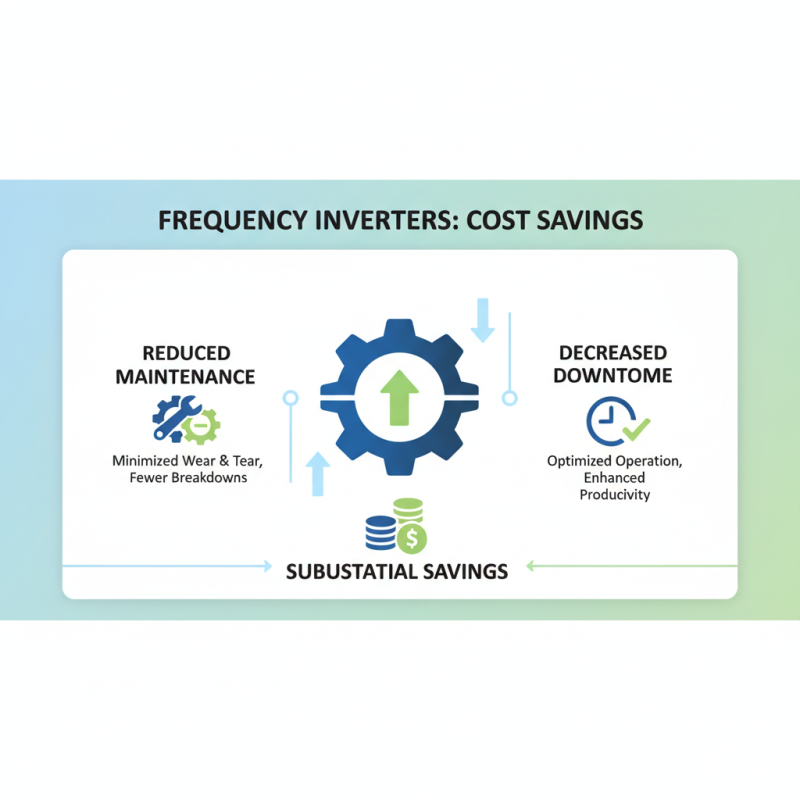

Cost Savings through Reduced Maintenance and Downtime

One of the most significant advantages of using frequency inverters is the potential for considerable cost savings linked to reduced maintenance and downtime. Frequency inverters allow for precise control of motor speeds, which can lead to a more efficient operation of machinery and equipment. By optimizing performance, these devices minimize wear and tear on motors and mechanical components, resulting in lower maintenance costs over time. With less frequent breakdowns and repairs, businesses can allocate their resources more effectively, enhancing productivity.

Additionally, the ability to adjust motor speeds on demand helps prevent overstressing equipment, which can lead to costly operational disruptions. Frequency inverters enable machinery to adapt to varying load conditions, ensuring that systems operate smoothly without unnecessary strain. This flexibility not only reduces the likelihood of unexpected failures but also extends the overall lifespan of equipment. As a result, businesses benefit from increased uptime and operational efficiency, translating into enhanced profitability and a healthier bottom line.

Versatility of Frequency Inverters in Various Industries

Frequency inverters, also known as variable frequency drives (VFDs), are becoming increasingly vital across various industries due to their adaptability and efficiency. One of the primary advantages is their ability to control motor speed and torque with precision, which makes them invaluable in sectors such as manufacturing, HVAC, and renewable energy. According to a report by MarketsandMarkets, the global VFD market is projected to reach $28.5 billion by 2025, growing at a CAGR of 4.4% from 2020. This growth highlights the versatility of frequency inverters in optimizing energy consumption and operational performance across numerous applications.

In the manufacturing sector, frequency inverters are leveraged to enhance the efficiency of conveyor systems, pumps, and fans, leading to significant energy savings. A study from the U.S. Department of Energy found that using VFDs could reduce energy consumption by 20-50% in these applications. Moreover, the agricultural industry harnesses frequency inverters to manage irrigation systems more effectively, ensuring optimal water usage while maintaining crop yields. Amid growing concerns over energy consumption and sustainability, the adaptability of frequency inverters signifies their essential role in driving operational efficiency and environmental stewardship across various sectors.

Top 10 Frequency Inverter Benefits You Must Know in 2023

| Benefit | Description | Application Areas |

|---|---|---|

| Energy Efficiency | Reduces energy consumption by adjusting motor speed and torque. | Manufacturing, HVAC, Water Treatment |

| Improved Process Control | Allows precise control of motor speed and torque for better process automation. | Food Processing, Chemical Plants, Packaging |

| Extended Equipment Life | Reduces mechanical stress on motors and drives. | Mining, Oil & Gas, Transportation |

| Cost Savings | Lowers operational costs through energy savings and reduced wear. | Construction, Agriculture, Textile |

| Flexibility | Easily adaptable for various motor types and loads. | Robotics, Aerospace, Automotive |

| Noise Reduction | Minimizes operational noise by controlling motor speed. | Commercial Buildings, Residential Applications |

| Regenerative Braking | Recovers energy during deceleration processes. | Elevators, Cranes, Electric Vehicles |

| Remote Monitoring | Facilitates real-time monitoring and diagnostics. | Industrial Automation, Smart Grids |

| User-Friendly Interface | Simplifies the setup and operation for users. | Small and Medium Enterprises, Homeowners |

| Environmental Benefits | Decreases carbon footprint by promoting energy efficiency. | Renewable Energy, Green Manufacturing |

Related Posts

-

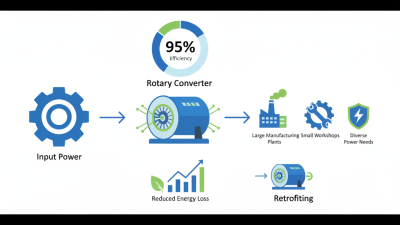

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency

-

Transforming Power: The Ultimate Guide to 400Hz to 60Hz Converters for Modern Applications

-

Why You Should Choose a Rotary Converter for Your Power Needs

-

How to Choose the Best Single Phase to Three Phase Converter for Your Needs

-

2025 Top Power Converter Solutions for Efficient Energy Conversion in Industry

-

The Future of Energy Solutions Understanding the Importance of Hz Converter Technology