Ultimate Guide to Understanding Phase Converters for 1 to 3 Power Conversion

In today's industrial landscape, the need for efficient power conversion is more critical than ever, particularly as businesses seek to maximize productivity and reduce operational costs.

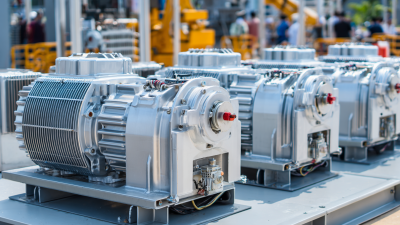

Phase converters are emerging as a vital solution in this realm, enabling the conversion of single-phase power to three-phase power. According to a report by the United States Department of Energy, about 80% of industrial motors operate on three-phase systems, making phase conversion systems essential for numerous applications.

The process of phase converter 1 to 3 not only ensures compatibility with three-phase machinery but also improves energy efficiency by allowing the use of existing single-phase power sources.

This guide aims to demystify phase converters, providing insights into their types, functionality, and the advantages they offer to various industries, ultimately supporting a seamless transition to more efficient power systems.

Phase converters are emerging as a vital solution in this realm, enabling the conversion of single-phase power to three-phase power. According to a report by the United States Department of Energy, about 80% of industrial motors operate on three-phase systems, making phase conversion systems essential for numerous applications.

The process of phase converter 1 to 3 not only ensures compatibility with three-phase machinery but also improves energy efficiency by allowing the use of existing single-phase power sources.

This guide aims to demystify phase converters, providing insights into their types, functionality, and the advantages they offer to various industries, ultimately supporting a seamless transition to more efficient power systems.

Key Concepts of Phase Conversion: An Overview for Beginners

Understanding phase converters is essential for anyone interested in converting single-phase power to three-phase power. This process is vital for operating three-phase equipment, which is commonly used in industrial applications. A phase converter essentially allows single-phase electrical systems to operate machinery designed for three-phase power, broadening the range of devices available for use in homes and businesses.

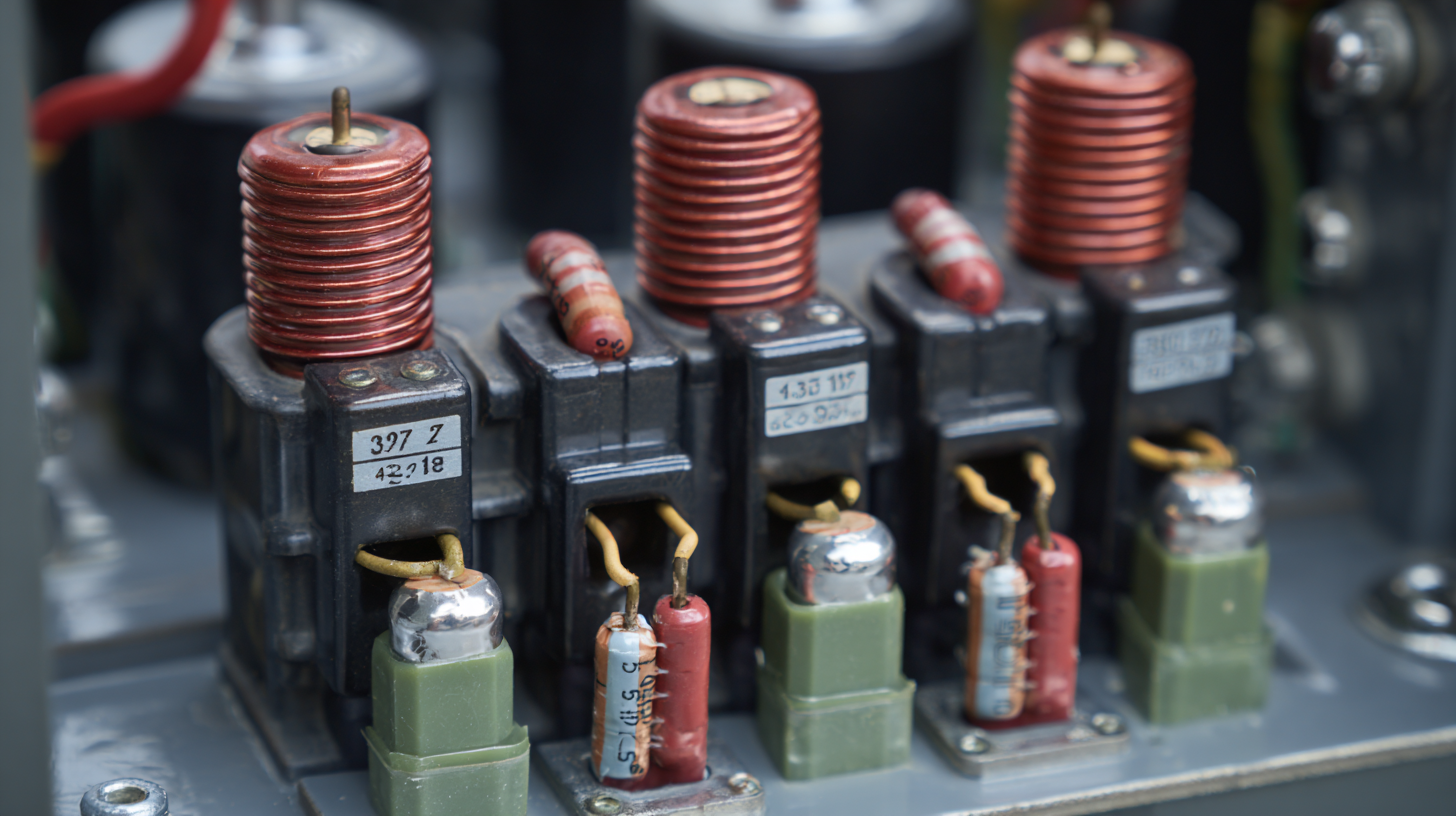

For beginners, grasping the key concepts of phase conversion can appear daunting, but it's vital to break it down. The three primary types of phase converters—rotary, static, and digital—serve different needs depending on power requirements and application types. Each type has its advantages; for instance, rotary converters provide a more stable power supply, while static converters are often more affordable. Understanding these differences will help users make informed decisions about which phase converter best suits their specific needs, ensuring optimal performance and efficiency for their equipment.

Understanding Phase Converters: Power Conversion from 1 to 3 Phases

This chart illustrates the efficiency of different phase converters used for converting single-phase power to three-phase power across various load types.

Types of Phase Converters: Choosing the Right One for Your Needs

When it comes to converting single-phase power to three-phase power, understanding the different types of phase converters is crucial for making the right choice for your needs. The primary types include rotary phase converters, static phase converters, and digital phase converters, each offering unique advantages. Rotary phase converters are ideal for running multiple three-phase loads simultaneously, providing consistent power and efficiency. They are typically larger and require more installation space, making them suitable for workshops or industrial settings.

Static phase converters, on the other hand, are simpler and less expensive, making them a popular choice for lighter loads or applications that don’t require running multiple machines at once. While they are easy to install and operate, they can result in reduced efficiency and performance under certain conditions. For those seeking high-performance and improved efficiency, digital phase converters are a modern solution that offer superior control and stability. They are also compact in size and can handle varying loads without compromising power quality. Understanding these differences will help you select the phase converter that best aligns with your operational requirements.

Installation Guide: Step-by-Step Process for Phase Converter Setup

When setting up a phase converter, it is essential to follow a systematic approach to ensure optimal functionality and longevity of the equipment. The installation process can generally be categorized into several key steps. First, it's crucial to select the right type of phase converter based on the specific requirements of your application. According to industry reports, properly sized converters can enhance equipment efficiency by up to 30%, ensuring that motors operate smoothly across varying loads.

Once the appropriate converter is selected, the installation begins with preparing the site, which includes ensuring that you have a stable electrical supply and adequate ventilation around the converter unit. As outlined by electrical standards, grounding the system properly is vital to prevent electrical faults and enhance safety. The setup of electrical connections should follow manufacturer guidelines closely, which often emphasize that incorrect wiring can lead to significant performance issues or even damage to connected equipment.

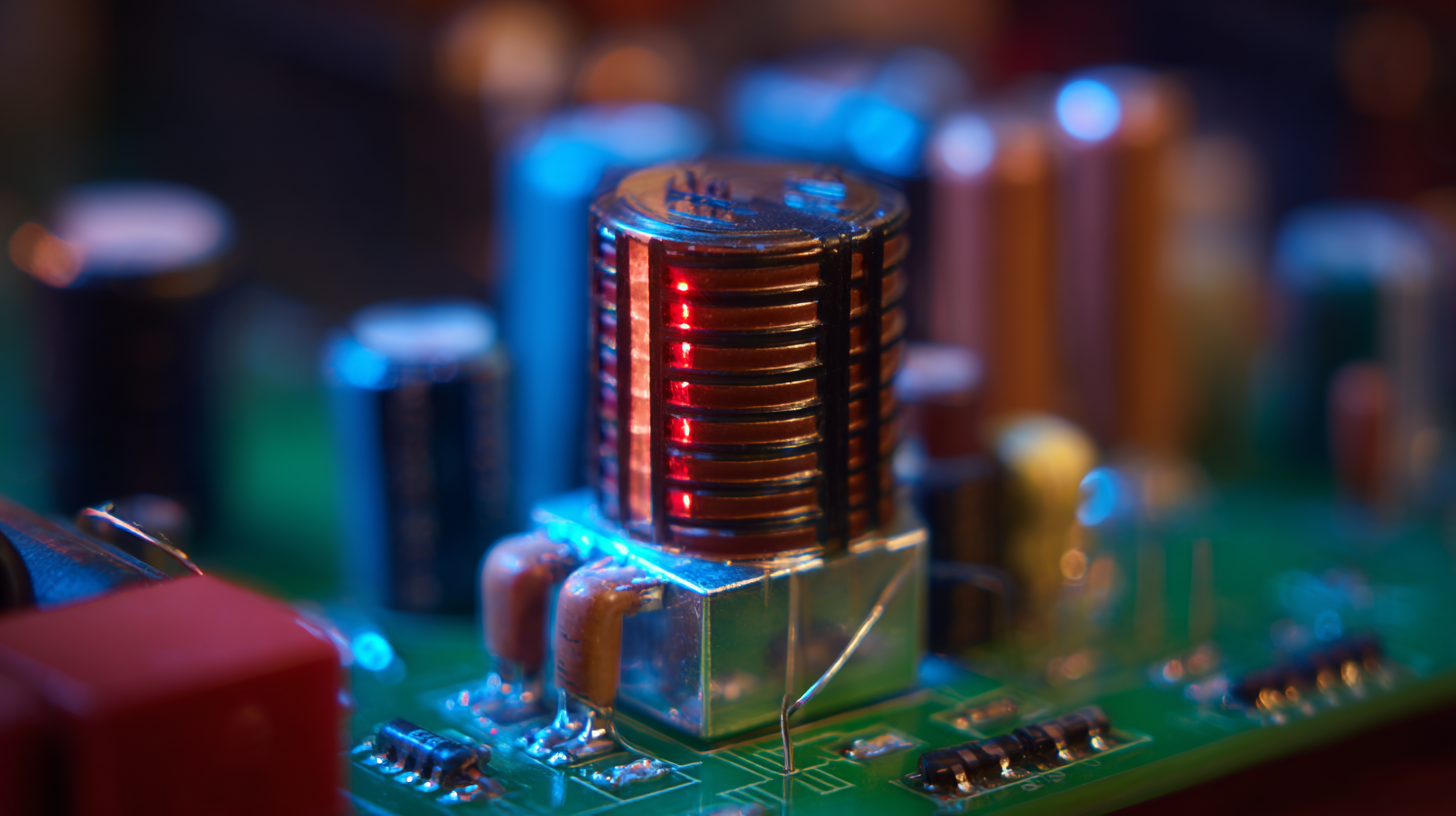

Calibrating the converter after installation is another step that cannot be overlooked. Industry studies indicate that poorly calibrated converters may lead to voltage imbalances, causing motors to run hot or inefficiently. Therefore, performing thorough testing is key to confirming that each motor is receiving the correct phase voltage, paving the way for reliable and effective operation in your facilities.

Troubleshooting Common Issues with Phase Converters

Phase converters are essential devices for converting single-phase power into three-phase power, enabling the operation of three-phase equipment in residential or commercial settings. However, like any electrical device, they can encounter issues that may hinder their performance. Understanding these common problems—and knowing how to troubleshoot them—can save time and money.

One common issue is inadequate voltage output, which can cause motors to run sluggishly or not at all. If you experience this, check the connections and ensure that the phase converter is matched appropriately to the load it’s driving. Additionally, using a voltmeter to measure the output voltage can help diagnose the problem. If necessary, consider resizing the converter to better meet your equipment's demands.

Another frequent concern is overheating of the converter. This can be attributed to overloading or poor ventilation. To prevent overheating, regularly inspect the cooling fins and ensure that the unit is placed in an area with good airflow. If overheating persists, reduce the load on the converter or consider installing additional cooling measures. Remember, routine maintenance is key to prolonging the life of your phase converter and ensuring optimal performance.

Maintenance Tips for Ensuring Long-lasting Phase Converter Performance

Regular maintenance is crucial for ensuring the longevity and optimal performance of phase converters, which are essential for converting single-phase power to three-phase power for various industrial applications. To start, it’s important to conduct routine inspections of the converter's components. This includes checking electrical connections for signs of wear, corrosion, or loose wires. Properly tightened connections can prevent an increase in electrical resistance, reducing the risk of overheating and potential equipment failure.

Additionally, keeping the phase converter clean is vital. Dust and debris accumulation can impair performance by affecting the cooling efficiency of the unit. Regularly cleaning the air vents and fan areas ensures adequate airflow and prevents overheating. Furthermore, inspecting and replacing any worn-out components, such as capacitors and relays, can significantly extend the life of the converter. Implementing a maintenance schedule that includes both visual inspections and functional testing can help catch potential issues early, ensuring that your phase converter continues to run smoothly and efficiently for years to come.

Related Posts

-

How to Seamlessly Upgrade from Single Phase to Three Phase Power Systems

-

Step-by-Step Guide: How to Effectively Use a Single to Three Phase Converter in Your Projects

-

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency

-

How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs

-

Comprehensive Guide to Choosing the Right Voltage Frequency Converter for Optimal Performance

-

How to Choose the Right Electronic Converter for Your Business Needs